The correct way to open the process of soft furniture production!

In recent years, with rising living standards and changing consumer attitudes, upholstered furniture has gradually entered the mainstream, and its share of the market continues to rise. Looking back at the Shanghai Furniture Fair in September, not only did panel furniture rise rapidly like a "dark horse," but upholstered furniture also received a certain degree of popularity.

Upholstered furniture primarily refers to furniture made of sponge or fabric. Examples include sofas and beds made of casual fabric, genuine leather, imitation leather, or leather and fabric. Currently, a large production base for upholstered furniture has been established in China.

Soft sofa

soft bed

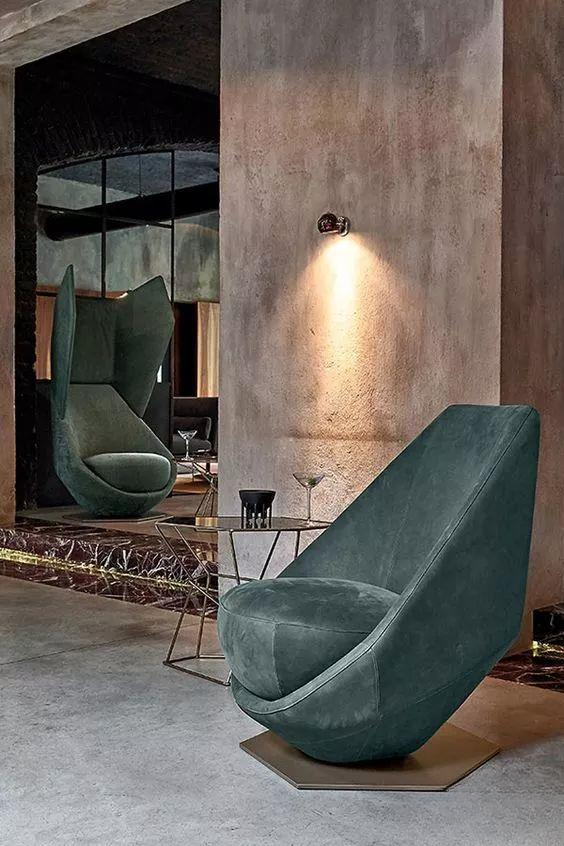

Soft chair

Soft wall panels

Upholstered furniture is gaining widespread popularity due to its elegant colors and clean lines, which complement various styles of living rooms and exude a unique charm. A popular saying in the upholstered furniture industry is: "From the inside out, the frame is elasticized, and the exterior is covered with sponge leather." This phrase describes the process required to complete an upholstered piece of furniture. So, what is the complete production process for upholstered furniture? Let's take a look.

1. Choose a framework

The frames of upholstered furniture are most commonly made of wood, although newer options include combinations of steel, plastic, and laminate. Bark and imperfect kiln-dried wood are often used for the frames. Frames like the legs, arms, and back of a sofa may be made of maple, but sometimes mahogany, walnut, or fruitwood is used for carved legs or moldings.

2. Assemble the frame

Assemble the prepared plates, bent parts, and square materials into a frame and seal the bottom plate. The frame strength must meet the requirements and the process must be convenient for subsequent operations.

3. Filling ingredients

Generally, soft furniture is filled with sponge. The sponge should be marked and cut according to the specifications and dimensions required by the material list. For sponges with complex shapes that need to be cut to fit, a material list and template should be attached to facilitate construction.

Some upholstered furniture is filled with animal hair, typically pig or horse hair. Some pre-treatment of the filling is necessary, such as cleaning the impurities from the filling, and the hair also needs to be glued into shape.

Some upholstered furniture cushions are made from polyurethane foam, polyester, down, cotton, latex, or cotton-wrapped springs. They can also be covered with synthetic, natural, or blended fabrics. Wool and nylon are the best natural and synthetic fiber options.

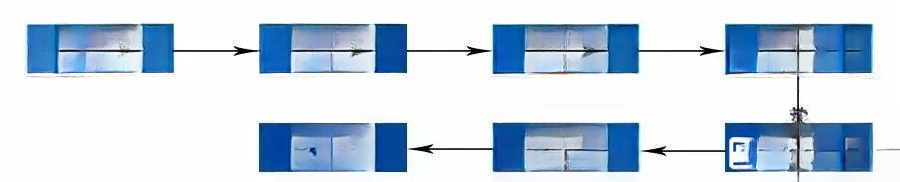

4. Paste the frame

Nailing elastic bands, gauze, and thin or thick sponges to the frame prepares for the leather-covering process, reducing the workload. This process requires specific requirements for the elastic band's specifications, quantity, tension, and crossing sequence, all of which affect the comfort and durability of upholstered furniture.

5. Jacket cutting

Cut according to the sample according to the ingredient list. Natural hides must be inspected individually to avoid any scratches or defects. Synthetic materials can be cut in stacks using electric shears. We make rational use of precious natural hides, selecting materials according to their quality and avoiding overkill. Coat cutting is a key production cost control point.

6. Coat sewing

The cut coats are sewn into coats, cushion covers, etc. on different sewing equipment according to different process requirements. There are many types of sewing equipment at present, and the seams of soft furniture are also constantly evolving.

7. Touch the skin

The pasted frame, processed inner and outer covers, various decorative parts and accessories are assembled into soft furniture. The general process is to nail the inner cover on the sponge-covered frame, then put on the outer cover and fix it, then install the decorative parts, nail the base fabric, and install the feet.

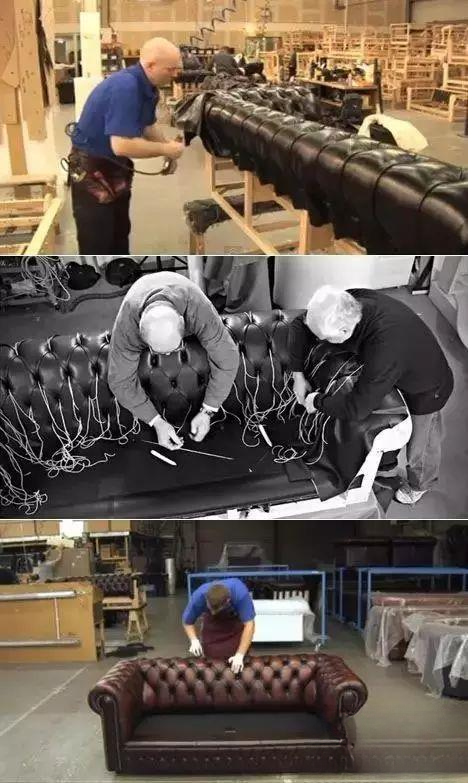

Foreign soft furniture production process

From the video we can see that the craftsmanship of purely handmade soft furniture is no less exquisite than that of solid wood furniture. In comparison, soft furniture is more environmentally friendly, but how should we maintain soft furniture during use?

1. Avoid sunlight: When placing soft furniture, it should be avoided from direct sunlight and away from heat dissipation objects to prevent the soft furniture from aging.

2. Dust removal: Vacuum soft furniture at least once a week, paying special attention to removing dust between the fabrics.

3. Turn the mattress over regularly: After using the soft furniture cushion for a period of time, turn it over or reverse it to evenly distribute the wear and tear, thereby increasing the service life of the mattress.

4. Cleaning: If soft furniture is stained, you can wipe it off with a clean cloth dipped in water. In order to avoid leaving marks, it is best to wipe from the outside of the stain .

The market competitive advantages of soft furniture are becoming increasingly apparent. Soft furniture companies have large production bases in cities with developed furniture industries, such as Beijing, Chengdu, and Guangdong. The development of soft furniture is also maturing step by step under the impetus of large-scale furniture production.