The birth of the sofa | The production process and process of a sofa

The basic production process of a sofa set can be divided into: making the sofa frame, laying the foundation, cutting the sofa feet, coloring the sponge, gluing and nailing, and then finishing the sofa set with a cover.

Before the sofa is made, it is necessary for experienced craftsmen to draw the pattern. Without a good pattern, it is impossible to make a good sofa. Because every joint needs to be carefully calculated, and a slight difference in the appearance will not be a small difference.

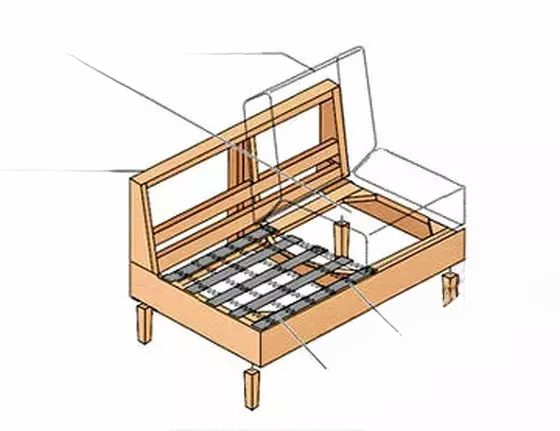

After the board is ready, the sofa frame will be officially made. The current sofa frame is mainly divided into two materials: solid wood and composite board. The sofa frame is similar to the human skeleton and supports the entire sofa. The firmness of the sofa frame structure and the rationality of the design angle will affect the quality and use function of the sofa.

Because wood contains moisture, the moisture content of wood can be controlled within 12% by drying, which can greatly reduce the deformation rate of wood. It is not easy to deform, rot and be eaten by insects.

The cushion area is covered with a breathable mesh fabric, which can effectively prevent moisture and allow ventilation, thus increasing the life of the sofa.

(2) Wrap the sponge around the outside of the sofa frame.

After that you can see a leather sofa like this——

Or a fabric sofa like this——