Solid wood furniture, understand these concepts and you won’t be afraid of stepping into the pit

This article comes from the sharing of group member "Wu Xiaodi". I was shocked after reading it. She told me before that she had no time and energy to take care of decoration, but I didn't expect that she could study it so deeply as soon as she started decorating.

Buying a house is also a matter of fate. Considering many factors, such as the convenience of my children's schooling and living, I also happened to see a house I liked at first sight. I signed the contract in April and finalized the renovation company in July. Then I joined the vast army of renovation workers. I hadn't renovated in ten years and was a complete novice in the field. After discussing my family's living habits, aesthetic preferences, and budget with the designer, we decided on a minimalist American style. The first step in decorating is to develop a furniture strategy. Furniture is the soul of the overall design and also the largest part of the budget. If it is a complete renovation, furniture expenses will account for about 40-50%, so the choice of furniture style, brand, and material is very important.

At the beginning of my renovation, friends who loved hanging out on forums pulled me into several renovation discussion groups. I then quietly crammed in renovation knowledge on forums and websites. However, faced with a vast amount of brand information and a multitude of differing renovation experiences, I was often confused and at a loss as to what to choose. I couldn't help but sigh that once you get into renovation, it's like diving into a deep sea... Of course, hard work also has its rewards. After more than a month, I finally figured out all the details about solid wood furniture. Today, I'll discuss the confusing concepts and standards in the solid wood furniture market. The solid wood furniture industry is generally quite chaotic. Although there are many manufacturers, from large-scale brand merchants that produce and sell directly to OEM companies that separate production and sales, from personalized customization merchants to small single-product woodworkers, the industry as a whole is still quite mixed. Previously, a group member complained about a well-known brand of wooden doors. Not long after installation, they developed very poor quality problems such as cracking and moisture. It was really frustrating, and of course, trust in such brands also plummeted to zero.

1. Let’s first talk about the pitfalls in the solid wood furniture market

1. Are all furniture called "solid wood" made entirely of solid wood? Currently, there's no strict definition of solid wood furniture in the wood market, or rather, the term "solid wood furniture" is rather broad. The commonly used concept is that furniture made with a solid wood base material (the majority of the main material) is considered solid wood furniture. Solid wood as a base material should be strictly distinguished from artificial wood panels. Therefore, wooden furniture can be categorized by material composition into three types: pure solid wood furniture (log furniture), which consists entirely of solid wood, without artificial wood panels . Composite solid wood furniture (a combination of wood and board) typically uses solid wood for the frame and load-bearing components, while auxiliary materials like side panels and back panels are made of artificial wood panels like multi-layer board and density board, with a veneer of solid wood bark applied to the surface to create the textured look of solid wood. Artificial wood panel furniture, on the other hand, uses artificial wood panels for both base and auxiliary materials. Because pure solid wood furniture is very expensive, solid wood is difficult to bend and shape, and natural wood is prone to cracking, pure solid wood furniture is rare, leaving composite solid wood furniture more common on the market. For example, Harbor House and Markor Home Furnishing, which are both priced high in the market, also have composite solid wood furniture with board-wood structure.

2. Misleading consumers by substituting concepts on materials. For example, some businesses mislead consumers by misrepresenting cheaper rubber wood as oak, confusing poplar and elm, or claiming that furniture is made of imported wood in order to raise the value of the furniture. After all, ordinary consumers do not have the ability to identify the raw materials of wood from its appearance. In addition, particle board among artificial boards is gorgeously labeled as solid wood particle board. This word game is really ridiculous.

3. The material composition of the furniture is vague or inadequate. For furniture that combines wood and board, many store staff are unable to clearly explain the composition of the auxiliary materials, and retailers are accustomed to only listing the main material on labels. For composite furniture, the most commonly used auxiliary materials are man-made boards such as multilayer board, density board, and particle board. However, the differences in material quality and craftsmanship determine the differences in performance, environmental friendliness, and price of man-made boards. This topic will be discussed in detail later.

Is the E0 environmental standard currently advertised by businesses an absolute pollution-free standard? There are currently no legal regulations in China. The E0 standard (the highest environmental emission standard) advertised in the market actually originated in Europe, and many businesses are applying it. The highest standard in Europe is E1, and there's no such thing as E0. Even higher than E1 is F☆☆☆☆ (F☆☆☆☆ was established in Japan). The F☆☆☆☆ environmental standard is less than or equal to 0.3mg/L, while the European E1 standard is less than or equal to 0.5mg/L.In fact, the environmental protection department currently has a clear national standard for artificial boards, which is less than or equal to 1.5mg/L. The concept of EO grade is only used as an environmental reference standard and does not represent a zero-pollution environmental standard, unless the furniture is made of pure logs without any carvings or processing.

5. Currently, eco-friendly boards (paint-free or melamine-based boards) are widely used in cabinets. Are they completely environmentally friendly because they don't require paint? The concept of eco-friendly boards will be discussed later, but the fact that eco-friendly boards are paint-free is questionable. Both the melamine glue on the surface and the glue used in the core of eco-friendly boards emit a certain amount of formaldehyde, but the emission index depends on the specific material composition.

6. Does the more expensive solid wood furniture, the better? This view is seriously wrong. A well-known home furnishing brand uses high-priced, inferior domestic solid wood furniture, even veneered solid wood. Therefore, it is more practical for consumers to analyze and compare solid wood furniture based on multiple factors, including wood properties, material composition, and production process.

2. Comparison of the advantages and disadvantages of solid wood furniture and panel wood furniture

There is no doubt that solid wood furniture has more advantages. If you have a very generous budget for decoration, it is recommended to go straight for solid wood furniture. However, for most mass consumers like me, the price of solid wood furniture is far beyond the budget. In addition, there are fewer categories of solid wood furniture on the market, and the styles and shapes are relatively simple. They are more suitable for some simple Chinese, Nordic or Japanese decoration styles, so the style selection will be more limited.

Solid wood furniture:

Advantages: natural quality, natural and beautiful patterns, exquisite workmanship, exquisite and durable, green and environmentally friendly, less pollution

Disadvantages: Direct sunlight and proximity to fire can cause a decrease in the moisture content of solid wood furniture, leading to cracking and deformation of the furniture, requiring careful care. The components of solid wood furniture are usually connected using mortise and tenon structures and adhesives. The finished product is generally not removable, making installation very inconvenient. In addition, solid wood furniture has high maintenance requirements, and good things are naturally more expensive. If conditions permit, solid wood furniture is best protected from dryness and moisture, insects and dust, and cleaned thoroughly. It is best to regularly maintain pure wood furniture with polish wax. The most important thing is, in one word, expensive! So it feels like the label for consumers of all-solid wood furniture is "tycoon"!

Panel furniture:

Advantages: a variety of colors and styles, fashionable appearance, not easy to deform, very convenient to disassemble and relocate, and the maintenance requirements are not high. Just place it stably, remove dust and sun protection, and maintain moderate humidity.

Of course, the key is that the price is relatively more affordable. Compared with the prohibitive price of solid wood furniture, the price of panel wood furniture is much more affordable.

Disadvantages: Various additives and adhesives are added to artificial boards during the production process. If the veneer is not properly processed, it will emit a large amount of harmful substances, such as formaldehyde and benzene, which pose a threat to human health. Therefore, the production process requirements of board wood furniture are very important. Similar to the edge banding machines used by cabinet manufacturers, there is a big difference between domestic and imported ones.

Environmental protection is the fatal flaw of panel furniture, but with the improvement of technology, the environmental protection coefficient of current artificial board products has been greatly improved. When consumers choose panel furniture, they must pay attention to the scale, technology and reputation of the manufacturer.

3. The pros and cons of artificial boards

There are countless types of wood panels, so today we'll discuss several common types. The factors that influence formaldehyde release from wood panels are primarily two: 1. The raw materials used; 2. The adhesives and glues used in the manufacturing process. So, what exactly are the differences in the raw materials used to make wood panels? Understanding these concepts will undoubtedly help furniture dealers avoid misleading you.

There are three main types of man-made boards on the market: plywood, particleboard, medium density fiberboard (MDF), and blockboard.

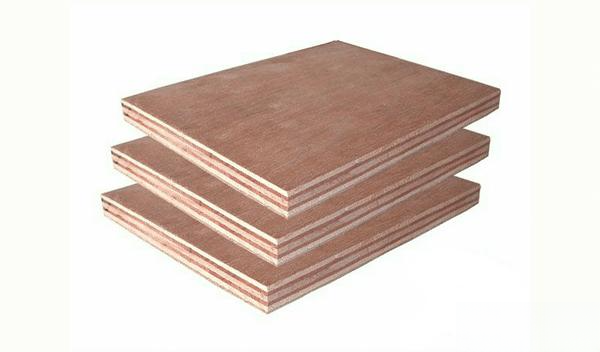

1. Plywood (also called multi-layer board or composite board) is made by gluing together layers of solid wood veneers. It is made by hot-pressing three or more layers of single or thin wood sheets. Plywood is generally available in six sizes: 3cm, 5cm, 9cm, 12cm, 15cm, and 18cm (1cm is 1mm). It is currently the most commonly used material for handmade furniture. Multi-layer board has the advantages of minimal deformation, high strength, and excellent internal quality. However, it is more expensive than the other two types of man-made board. The market price is approximately 2,000 to 3,000 yuan per cubic meter.

2. Particleboard (also known as solid wood particleboard on the market) is made of wood or other lignocellulosic materials, with fine wood fibers on both sides and long wood fibers in the middle. These are bonded together using heat and pressure after adhesive application. It is less durable and environmentally friendly than solid wood eco-friendly boards and solid wood multi-layer boards.

Why is particle board now called "solid wood particle board"? Two words: hoax. The term "solid wood particle board" was coined by businesses. People are increasingly demanding environmental protection and quality. Many people believe that solid wood is pollution-free, environmentally friendly, durable, and beautiful... but solid wood is too expensive. Particle board, being made from sawdust mixed with a large amount of industrial glue, contains sawdust. So, businesses cleverly coined a new term: solid wood particle board.

Solid wood particles are cheap and easy to assemble. Once installed, never remove them! Because the board is made of compressed wood chips or mixed with other materials, it still lacks strength.

Fiberboard (also called density fiberboard ) is made by gluing together finer wood fibers (wood is ground, steamed, and pulped to remove excess water). It is categorized by fiber density: low-density fiberboard, medium-density fiberboard, and high-density fiberboard. Medium-density fiberboard offers better performance than low-density fiberboard and lower cost than high-density fiberboard. It also has a strong nail-holding capacity and is easy to shape. However, density fiberboard is sensitive to water and moisture, so it's not recommended for kitchen and bathroom furniture.

4. Blockboard is also known as core board, wood core board, and woodworking board. It is made of two veneers glued together. The wood blocks inside are mostly made of cheaper wood such as pine and fir.

Compared to particleboard and medium-density fiberboard, blockboard's natural wood properties better align with human needs for a natural ecosystem. It offers advantages such as light weight, ease of processing, excellent nail holding power, and resistance to deformation. Compared to solid wood, blockboard is dimensionally stable and less susceptible to deformation, effectively overcoming wood anisotropy and possessing high transverse strength. By strictly adhering to the principle of symmetrical assembly, blockboard effectively avoids warping and deformation. Blockboard's aesthetically pleasing surface, wide width, and ease of use make it an ideal material for interior decoration and mid- to high-end furniture.

Eco-board (paint-free board) is a general term referring to boards that meet certain environmental standards. In terms of manufacturing, eco-board is a wood-based panel veneered with melamine-impregnated paper. Paper with different colors or textures is soaked in an eco-board resin adhesive, dried, and then laid onto plywood, blockboard, or spliced solid wood. The resulting decorative panel is heat-pressed. The melamine film on the surface of eco-board contains limited formaldehyde and is relatively volatile. Therefore, although they are all collectively referred to as eco-board, products made from different substrates vary greatly, including adhesive content. Therefore, the internal material structure of eco-board must be clearly defined. Because eco-board does not require painting, it is suitable for furniture made on-site by carpenters and is currently widely used in wardrobe cabinets.

In addition to the above types of boards, we will also see board categories such as Egger board and Australian pine board on the market. This type of board is an artificial board imported from Europe. From the production process, it should be classified as medium-density fiberboard. Due to the difference in the composition of its wood chip materials and the pressing process, the product's environmental friendliness and stability will be slightly higher than the same type of domestic board. Of course, the price will also be higher.

A major difference between artificial boards and solid wood is the presence of adhesives. Adhesives are the primary source of formaldehyde in artificial board furniture. The better the adhesive, the lower the formaldehyde emissions, but the higher the cost. From an environmental perspective, plywood and blockboard, primarily made of solid wood, contain lower adhesives than particleboard and MDF.

b. In terms of strength, MDF is stronger than plywood and particleboard. However, plywood and particleboard are also widely used in non-load-bearing parts of furniture because of their lower cost.

C. Because MDF and particleboard contain a large amount of glue in their cores, they require mechanical edge sealing. Poor edge sealing can directly lead to the release of formaldehyde from the core. Plywood and core board can be soft-edged and can be completed by on-site carpentry, making them more suitable for on-site furniture production.

D. Comparing prices, core boards and eco-friendly boards are slightly more expensive, generally around 2,000 to 3,000 per cubic meter. MDF and MDF are cheaper, around 1,000 to 2,000 per cubic meter.

4. Things you must know about natural wood

The natural and original beauty projected by solid wood furniture is incomparable to artificial boards. Natural wood corresponds to a wide variety of tree species in nature. The price of wood has a lot to do with the beauty and physical properties of the tree species. Of course, different tree species are suitable for different furniture use categories due to their different physical properties. For example, the wood that can be used to make entire pieces of furniture is now more commonly oak, ash, walnut, elm, beech, catalpa, rubber wood, oak, etc., while the precious mahogany furniture mainly uses rosewood, wenge, and red sandalwood. However, due to the darker color of mahogany furniture, the difficulty of shaping and processing, and the high price, young people currently do not have many choices.

Natural wood has its own strengths and weaknesses, and there's no absolute superiority or inferiority. Therefore, there's no need to dwell on specific differences in wood's physical properties. Most wood used in the furniture industry meets the requirements for strength, durability, and corrosion resistance. The key is to choose and compare materials based on your own aesthetic preferences and price. The attached table provides essential information about commonly used woods for solid wood furniture. Understanding these concepts will help you avoid pitfalls.

Appendix 1: Comparison of characteristics of commonly used woods for solid wood furniture

Walnut, also known as walnut, comes in various varieties, including black walnut, golden walnut, and red walnut. It is primarily produced in North America and Europe, with smaller quantities also found in Southeast Asia and China. It is one of the world's most prized woods, and is considered one of the three most valuable woods in Europe, along with walnut, mahogany, and oak. Black walnut is light dark brown with purple, and its tangential section displays a beautiful large parabolic pattern, with a distinct grain and rich color. Walnut has a medium to slightly hard hardness, a fine and uniform fiber structure, and strong toughness. It is particularly resistant to vibration and wear, has a certain degree of bending resistance, and its heartwood is highly resistant to corrosion, making it one of the most durable woods even in corrosion-prone environments. It is relatively expensive and is used in various types of furniture, cabinets, and other areas.

Cherry wood, which can be divided into European sweet cherry, fruit cherry, Japanese cherry, and American cherry, is primarily found in the eastern United States. It is a high-quality wood with a straight grain. The heartwood ranges from bright red to brownish-red, and the sapwood is creamy white. Cherry wood naturally contains brown heartwood spots and small gum pockets. It has a fine, crisp grain, polishes well, and takes well to paint. It has good machinability and bending properties, low hardness, medium strength, and resistance to impact loads. It also has low tool wear and excellent nail holding, adhesive strength, and polishability. It is relatively expensive and is used in flooring, pipes, musical instruments, furniture, and cabinets.

Redwood, a group of 33 species, including sandalwood, rosewood, and wenge, originate primarily in India. They are also found in Guangdong, Yunnan, and the Southeast Asian Islands. They are common and valuable hardwoods. "Redwood" is a popular term in Jiangsu, Zhejiang, and northern China. In Guangdong, it's commonly known as "suanzhimu." Redwood is a general term for high-end, premium furniture. The term originated in the late Qing Dynasty, when it referred to hardwoods with deep red heartwood, such as rosewood imported from Southeast Asia. Modern standards for redwood have been revised, classifying 33 species as redwood. These include sandalwood, rosewood, and ebony, though some of these woods are not always red. The wood has a uniform color, ranging from light yellow to dark reddish-brown, with visible dark streaks. It has a lustrous, light or noticeable aroma, and a fine, even texture (slightly coarser in South American and African woods). It is wear-resistant, durable, heavy, and strong, with a darker color. It often reflects an antique style and is used in traditional furniture. Its hard texture, high strength, wear resistance, and durability are excellent. The disadvantages are that it is difficult to process, is relatively greasy, is not resistant to sunlight, and is relatively expensive.

Oak, also known as oak, white oak, red oak, and Northeastern oak, are sometimes also called oak. They belong to the same plant family and are primarily grown in Europe and North America, with significant production coming from Russia and the United States. They are widely distributed in the eastern United States. The wood is hard, heavy, and easy to work with. The color, grain, characteristics, and properties of red oak vary depending on its origin. Southern red oak grows faster than northern red oak, and the wood is harder and heavier, resulting in a significant price difference between the north and the south. Oak has a distinctive, chevron-shaped grain and a pleasant feel. It is characterized by its hardness, straight grain, and coarse structure. It is mechanically strong and wear-resistant. Oak also has a pattern that varies between straight and horizontal grain, with straight grain being more attractive and offering greater toughness. Oak is not easily absorbed by water and is highly resistant to corrosion. However, the wood is not easy to saw and cut when dry, and is prone to deformation and cracking when used on large surfaces. It is above average quality and is suitable for flooring and various furniture.

Manchurian ash, also known as white ash, is found in North Korea, Japan, Russia, and mainland China's Shaanxi, Gansu, Hubei, Northeast China, and North China. Naturally cold-loving, it can reach heights of up to 30 meters. Its sapwood is light brown, and its heartwood is slightly darker than the sapwood. It is very cold-resistant and is a prime choice for furniture. Its wood is yellowish-white (sapwood) or slightly yellowish-brown; its growth rings are distinct but uneven, and its structure is coarse, with straight grain, beautiful patterns, and a lustrous finish. It is quite hardy and durable, boasting a beautiful texture, minimal color variation, and excellent corrosion and water resistance. It also takes well to stain and stain, and it also has excellent resistance to paint and adhesives. However, Manchurian ash lacks the decay resistance of its heartwood, and its whitewood (sapwood) is susceptible to infestation by powder beetles and common furniture beetles. It also resists drying and is prone to warping and cracking. It can deform significantly, so solid wood production often uses small pieces of wood, which can easily cause damage to the furniture. Large pieces of wood shrink and deform significantly, making them unsuitable for furniture of all types. It is moderately priced and suitable for all types of furniture.

Boxwood, also known as elm, is mostly grown in northern China. Its wood features interlaced grain and vibrant colors. Boxwood is a small evergreen shrub with a hard and fine texture, but it grows extremely slowly. Trees must be at least thirty years old to be used for carving, hence its nickname, "Millennium Dwarf." The wood is strong, resilient, corrosion-resistant, and durable. The interlaced grain of boxwood furniture is beautiful and natural, and the resulting solid wood is among the finest in the industry at an affordable price. Boxwood has a fresh, elegant fragrance that is refreshing but not overpowering, yet elegant yet not tacky. The wood is so fine that even the pores are invisible to the naked eye. It is suitable for furniture with carvings or inlays.

Catalpa wood, also known as walnut tree (native to Northeast China), is a southern species of catalpa wood. Grown in extremely cold regions such as Northeast China and Russia, it is known as the "King of Wood" and the "Golden Tree." It is one of the world's most famous woods, on par with Southeast Asian ebony and rosewood, and American maple. The wood has a moderate hardness and low density, and possesses physical and mechanical properties such as low shrinkage, a smooth planed surface, and strong wear resistance. It has a slightly coarse structure, beautiful color and pattern, and is resilient, resisting warping when dry.

It has good processing properties, good gluing, coating and coloring properties, and a tough, dense and fine texture. It is relatively expensive and is a high-quality material widely used in musical instruments, crafts, military industry, and rural-style furniture.

Beech, also known as "椐木" or "椇木", is produced in the south, Europe and North America. Beech was a common wood species in the ancient Jiangnan region. Most of the beech sold in China are imported and produced in Europe and North America. The wood has stable properties and is a medium to high-end furniture material. The wood is heavy, strong, and impact-resistant. It is easy to bend under steam, can be made into shapes, and has good nail holding properties. It is a wood unique to Jiangnan, with clear grain, uniform wood texture, soft and smooth color, natural and beautiful large patterns, and the color is similar to rosewood. It is heavier than most ordinary hardwoods and ranks in the upper-middle level in the hardness of all woods. It is moderately priced and used in furniture, shipbuilding, construction, bridges, etc.

Maple, also known as maple, soft maple and hard maple, has more than 150 species worldwide and is widely distributed in North America, Europe, northern Africa, and eastern and central Asia. It is a temperate wood with a gray-brown to gray-red color, inconspicuous growth rings, and numerous, small, and evenly distributed pores. It has good paintability and strong gluing properties. It is mainly used for thin-surface veneer for boards.

Maple ranges from creamy white to natural white, sometimes with a light reddish-brown hue. Western woods are mostly light gray-brown. Characteristics: The wood is dense, evenly grained, polishes well, occasionally exhibiting light green-gray mineral veins, and is easy to paint. Maple has moderate strength, fine quality, and a mid-to-high price point. It is suitable for flooring and furniture finishing.

Rubberwood, a subtropical tree species found in Hainan, Guangdong, Guangxi, Fujian, Yunnan, and Taiwan, is a fast-growing material. It grows in Hainan, Guangdong, Guangxi, Fujian, Yunnan, and Taiwan. It grows in southern and Southeast Asia, taking about 15 years to mature. It's a high-yield, economical, and inexpensive log. However, the wood is prone to cracking, warping, and discoloration, and has a strong sour and foul odor, as well as rotting and insect damage. However, it's relatively affordable and is used as a raw material for home furnishings, furniture, cutting boards, particle boards, wood core boards, and furniture accessories.

Pines, including Masson pine and Scots pine, have approximately 100 species distributed throughout the Northern Hemisphere. There are 22 species, with a widespread distribution across the east, west, south, north, and central regions, making them extremely important species for afforestation and timber production. Pine is a conifer (common conifers include pine, fir, and cypress). It has a pine scent, a pale yellow color, numerous scars, reacts quickly to atmospheric temperature, swells easily, and is extremely difficult to air-dry naturally. Therefore, it requires artificial processing, such as drying, degreasing to remove organic compounds, and bleaching to uniform the color and neutralize its properties to prevent deformation. Masson pine has a straight or uneven grain with a medium to coarse structure. Its disadvantages include severe warping and cracking during drying, poor corrosion resistance, and poor resistance to painting and gluing. Scots pine is widely used in mid-range solid wood furniture, and many solid wood furniture is made of pine. Pine is strong, has a clear grain, and is of high quality. Compared to fir, Scots pine has a more beautiful grain and fewer knots. It is moderately priced and widely used in children's furniture.

Chinese fir, also known as sandwood or sand tree, is found eastward in the mountainous coastal areas of Zhejiang and Fujian and the mountainous areas of Taiwan, westward in eastern Yunnan, the western edge of the Sichuan Basin, and the Anning River basin, southward from central Guangdong and central and southern Guangxi, and northward to the southern foothills of the Qinling Mountains, the Tongbai Mountains, and the Dabie Mountains. It is a unique fast-growing commercial timber species known for its rapid growth and high-quality timber, and is extensively cultivated. Consequently, Chinese fir is rarely used in furniture, but rather for pulp, blockboard, density fiberboard, particleboard, keels, and finger-jointed boards for furniture lining. Its fast growth and high-quality timber yield straight, uniform grain, light and tough wood, and moderate strength. Chinese fir has a fragrant aroma and contains "sugar brain," which is insect-resistant and decay-resistant, making it easy to process. Chinese fir is a softwood, but it has two major drawbacks. First, due to its fast-growing nature, with a maturity period of 4-6 years and rapid production, its naturally loose wood fibers and high moisture content make its surface soft and easily scratched by external forces. Second, it suffers from numerous scars, with black scars appearing at regular intervals. The price is relatively low and it is widely used in construction, furniture accessories, appliances, shipbuilding and other aspects.