I will introduce to you the sofa making process, hoping that you can have a better understanding of sofas and know what to pay attention to when buying sofas in the future, or it may be helpful for your preparations for opening a sofa factory. If you need help, please leave me a message.

1. Sofa frame production and base laying

▼Sofa frame production. Wood and composite board (plywood) are used. At present, the sofa frame is basically made of composite board. The advantages of composite board are easy processing, low cost, not easy to be infected with insects, not easy to corrode, and high strength. Wood generally needs to be dried.

▼Material specifications, generally the main structure is 2.6 cm thick, the main structure is made of a whole piece of solid wood, and it is double-sided polished. According to the grade of the sofa, the plane can be made of 0.2-0.4 cm plywood or composite paper.

▼Pay attention to details.

▼Pay attention to the precise sewing of the interface and do not be careless.

▼ Put rubber bands on the sofa back frame! Because the back frame does not bear as much force as the seat frame, rubber bands can be used. Some people also use so-called black leather belts, which are made from discarded tires.

▼The base of the sofa seat frame uses an S spring plus a small tension spring. Some people also use rubber bands or black leather belts on the seat frame, which has poor bearing capacity. Old-fashioned sofas in the past were not like this. This is the latest one.

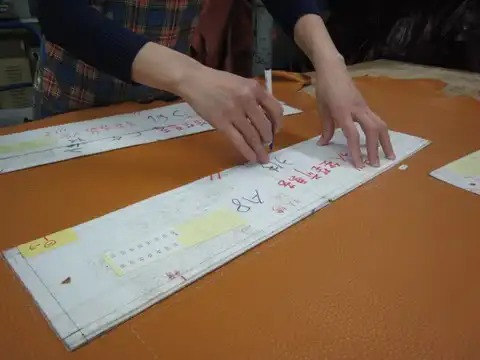

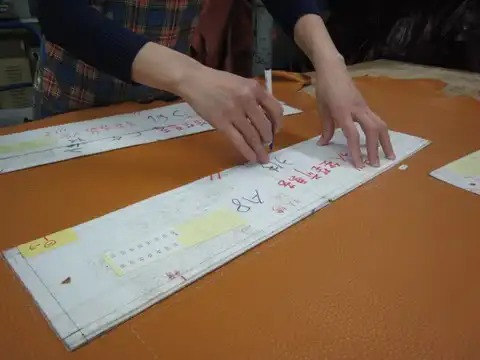

2. Cutting

▼The sofa you see has each surface made of a board, called a leather board. Place the leather board on the cowhide and draw it, and be careful to avoid unqualified leather. Then start cutting the leather. You can also use a blade to cut it. Of course, if it is cloth, you can use electric scissors, which can cut multiple layers at a time.

▼Leather cutting requires little technical skill, and all you need to do is get used to it and cut it beautifully, but this method is only suitable for small-scale production needs.

▼After cutting the leather, the sofa cushions, armrests, and backrests are classified and packaged so that the next "sewing" can be carried out smoothly and efficiently.

▼Sewing, flat car, will cut the leather, piece by piece, the sewing process is very important, related to the appearance of a sofa craftsmanship quality, this machine looks scary, like a Japanese heavy machine, Trayton Jiashan factory are all of this brand, look at its body, and the price is not cheap.

▼ Pressing visible stitches, using a single-needle machine, depends on the sofa design. It is a kind of decoration. Lines can be used to emphasize the shape of the sofa. The visible stitches are required to be freely spread, uniform in width, without tangled wires, and straight. If wiring is required, pull the thread ends from the wiring point to the back and tie a knot. Do not tangle the thread.

▼ Pressing the seam. Use a double needle to press the seam. It can be said to be a decorative line. This is because after the flat sewing machine is connected, when the leather surface is spread out on the front, two layers of leather will overlap at the joint of the flat sewing machine. Using a double needle to sew the overlapping parts firmly will not only prevent the joint from breaking, but also make it smoother when it is put on the sofa frame. Of course, the fineness and firmness of the double needle actually require a lot of knowledge!

▼This German PFAFF high-top double-needle sewing machine looks not much older than us. Haha!

3. Color the Sofa Legs

▼Dyeing should be done before spraying, because wood also has pores. Dyeing allows the color to absorb into the wood first, which will make it more beautiful when sprayed later.

▼ To spray paint beautifully and with fine workmanship, there are also skills! The older generation said, spraying paint? Just look at the gestures and the spraying method, and you will know! (It is hard to describe in words, just by feeling)

4. Foam bonding

▼It may seem simple to glue the sofa frame with foam, but whether it is glued accurately or not will have a great impact on the beauty of the finished product after the leather cover is nailed together!

▼The cushion foam is glued together. The structure is foam + latex + foam. These materials are generally of average quality, generally do not directly contact the human body, have less wear and tear, and play a supporting and filling role. Early sofas generally used leaves as fillers.

5. Nail binding and set sofa cover

▼ Pay attention to make sure it is flat and in place.

▼Hit the nails appropriately according to the surface of the sofa.

▼Put the leather seat cover onto the seat frame and use gun nails to properly position it according to the surface of the sofa.

▼The photo of the completed assembly after combining the above two.

▼After the sofa is completed, judging from the surface material, this set of sofas is of relatively high-end quality, and the materials used in general sofas on the market cannot meet this standard.

The above photos are collected and organized by me to give you a simple concept of sofa making. Some steps may vary due to different sofa structures, but the basic production process is the same. It does not necessarily represent this production method and process. Everyone does this. I believe that with the innovation of the industry, sofa production will gradually move away from this production model. If you are interested in the sofa industry, you can learn from each other and you can ask any questions.

You can click the contact address: http://user.qzone.qq.com/162257722/infocenter

qq:162257722

Sofa manufacturing process Sofa manufacturing process Leather sofa production process Cowhide sofa production