Quickinstall parts make modern furniture more modern

With the development of society, furniture is also changing. Whether it is structure, function or appearance, it has the mark of the times. Modern furniture has various forms and styles. What can meet the diversity of furniture forms is furniture hardware, which is the carrier of modern furniture structure. It can be said that without modern furniture hardware, there would be no modern furniture. Furniture hardware plays an important role in many factors such as modern furniture function, structure, manufacturing process and shape.

But do you know what the original connections of panel furniture were like?

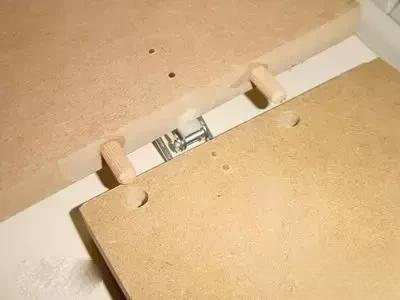

There is a big gap between artificial boards and traditional solid wood in many aspects such as density, hardness and texture, which means that the structure of furniture will undergo a major change. When people first studied the structural combination of panel furniture, they still used the mortise and tenon structure of traditional furniture as a reference and adopted the "drilling and planting" method.

Punch holes in the board and insert logs to achieve a concave-convex bite similar to the mortise and tenon joints. Glue is of course indispensable. The processing and assembly efficiency of this connection method can be imagined. It is not easy to transport, and the implanted tenons also affect the appearance.

Therefore, the original panel furniture was still solid furniture that could not be disassembled.

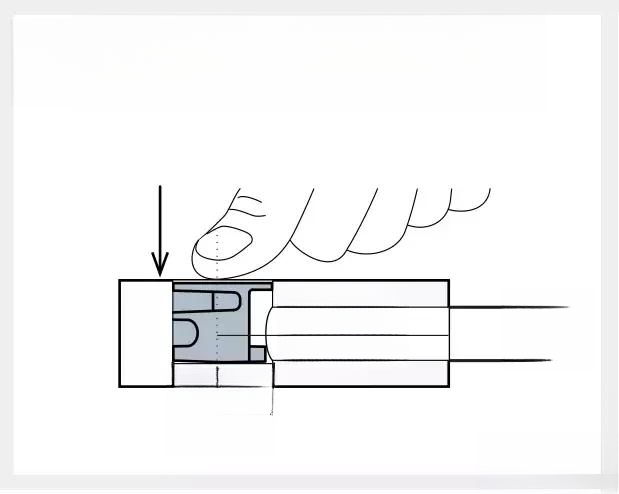

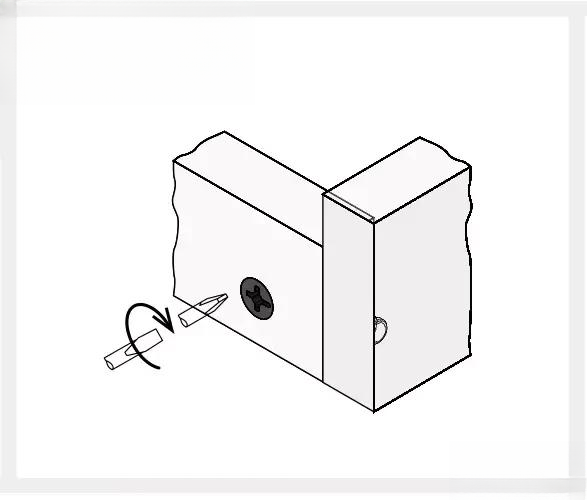

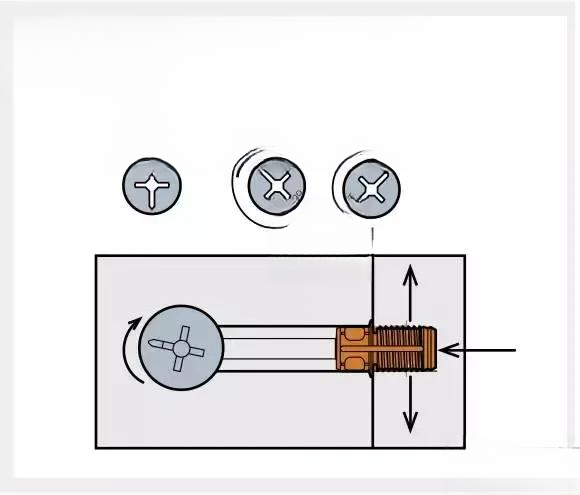

With the advancement of technology, the emergence of a small connector has directly brought panel furniture into the era of disassembly and assembly. This is the eccentric connector, also known as the three-in-one connector. As the name suggests, it consists of three parts: an eccentric wheel, a screw and embedded parts.

Today's panel furniture is all three-in-one, which realizes the "parts supply, on-site assembly" model of panel furniture, allowing panel furniture to be produced efficiently, with firm joints, and can be disassembled and assembled by yourself at will, without affecting the original appearance.

The epoch-making three-in-one has been used for so long. Have you ever thought about what the next era of panel furniture will be like? The connector to be introduced below will bring panel furniture into a new era.

The upgraded version of the three-in-one product - quick-release connector, can improve the installation speed and quality of panel furniture.

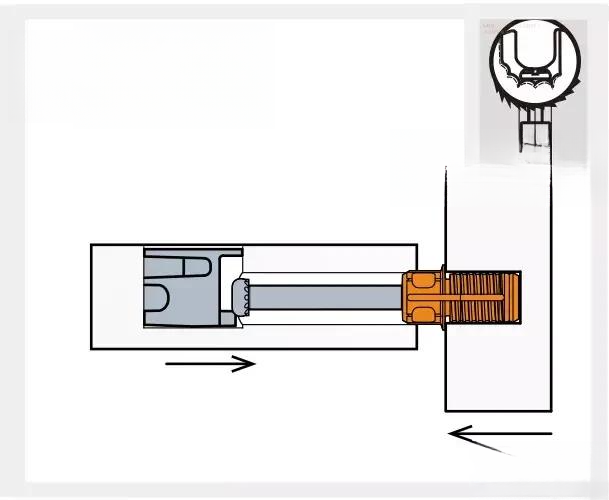

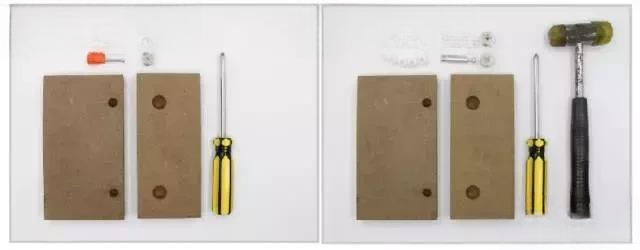

As we all know, the three-in-one is composed of an eccentric wheel, a screw and embedded parts, while the quick-install parts are equivalent to eliminating the embedded parts. There are only two parts, the connecting rod and the eccentric wheel. This saves the process of installing the embedded parts, and the overall installation speed is increased by 40%. It can also be disassembled and reused repeatedly.

At this point you may have the following questions:

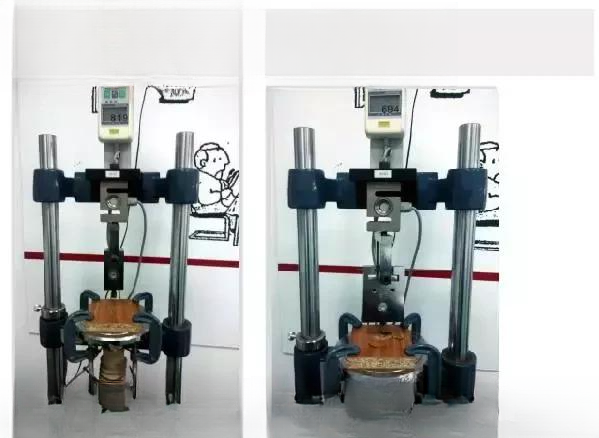

Q1. Although the quick-release parts eliminate the gap between the rubber plug and the connecting rod, how to ensure the tightness of the rubber particles and holes on the connecting rod? Will it affect the tension between the panels and the stability of the cabinet?

A: There is a locating medium between the screw and the handle of the quick-release screw. This locating medium is used to prevent the possibility of movement of the upper and lower spaces so as not to affect the tension and tightness of the cabinet connection.

Q2: Is the hole position and size of the 3-in-1 consistent? Does it affect the versatility?

A: It is the same as the three-in-one hole. It is just the installation size that is different, but the three-in-one itself is different in size. So, if you have used the three-in-one before, you can use the quick-release connector without changing the punching equipment.

Advantages of quick-release connections

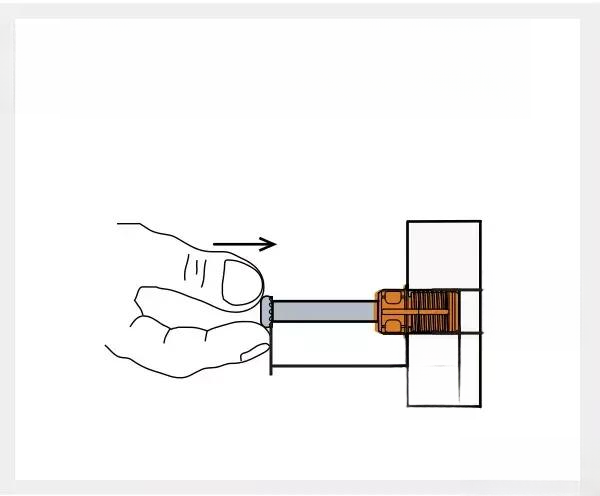

1. Fast and safe

It can be installed quickly without tools and can be achieved by pushing it in. It can be installed without glue bolts, which shortens the processing and installation time and reduces costs. It can be installed and disassembled by hand, avoiding the safety hazards of using tools.

2. More secure

Eliminate the gap between the rubber plug and the connecting piece. The greater the tension during installation, the tighter the connection. The positioning ring on the connecting rod and the rubber particle ensures the insertion depth. The inner and outer teeth of the fixing rod of the eccentric wheel are notified to achieve the insurance function, making the fixing position of the connecting rod better.

The quick-install parts eliminate the need for installing embedded parts, increasing the overall installation speed of panel furniture by 40%. They are also versatile and do not require replacement of punching equipment. They can even be disassembled and reassembled repeatedly while ensuring safety and firmness.

It is such an inconspicuous connector that plays a revolutionary role. Whether it is furniture manufacturing or daily life, any details cannot be ignored. Otherwise, how can we say that details determine success or failure?

It seems that quick-install parts have not been widely used yet and are still a new thing. However, in fact, they have begun to gradually change the way panel furniture is installed and distributed.