Learn carpentry from scratch and make sofas and coffee tables (Part 1)

I hope to have furniture that I can use for 20 years and still be reluctant to throw away. They accompany our lives and are engraved with the traces of time... Furniture made by myself can fulfill this wish.

This time I would like to share with you the process of learning carpentry from scratch and making sofas and coffee tables.

01 The sofa I want

We used to have a leather sofa against the wall. Less than half a year later, our son broke the leather by jumping on it (he likes to use the sofa as a trampoline). The bottom of the sofa became a concentration camp for all his toys and gadgets. Whenever he lost a toy, we moved the sofa away and the floor was a mess .

So, when we moved to a new home and replaced the sofa, our requirements were : (1) We didn’t want a leather sofa this time, but a fabric sofa with a removable and replaceable surface. (2) The bottom of the sofa should be raised so that the floor under the sofa can be cleaned when mopping the floor. (3) Because the living room of the new home is large enough, the sofa is not placed against the wall, so the back of the sofa must also be beautiful.

02 Can’t buy

We visited several furniture stores but couldn't find the sofas we wanted. Some of the fabric sofas we liked had non-removable tops. We finally found a sofa with a replaceable top and a raised bottom, but we didn't like the design on the back...

03 Design Your Own

Sofa design

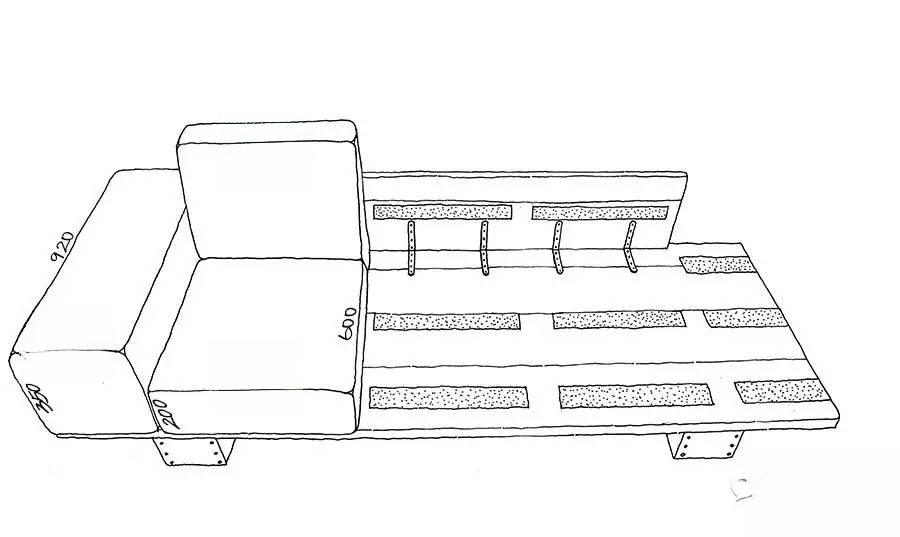

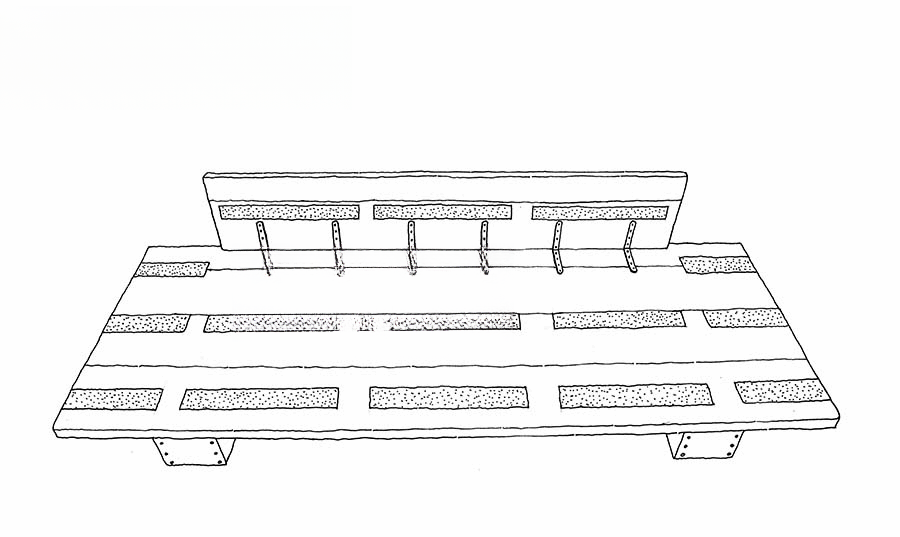

Taking into account our limited woodworking skills, we designed a simple and plain pine sofa frame, and matched it with sofa cushions customized online. The total cost was 2,500 yuan , which met all our requirements for the sofa.

Front of the sofa: pine wood sofa base + two rectangular sofa wooden blocks, strong and easy to make.

Back of the sofa: The pine wood back panel is spliced with steel bars, with simple craftsmanship, plain and beautiful appearance.

Coffee table design

Life experience tells us that the coffee table often needs to be moved to make room in front of the sofa for children to play. So we designed a coffee table that is easy to move and can be folded and unfolded freely.

The pine wood coffee table has wheels at the bottom for easy movement.

There are hinges on both sides for opening.

It fits perfectly under the sofa, freeing up a large area for playing.

04 Sofa production

Step 1: Make the Sofa Base

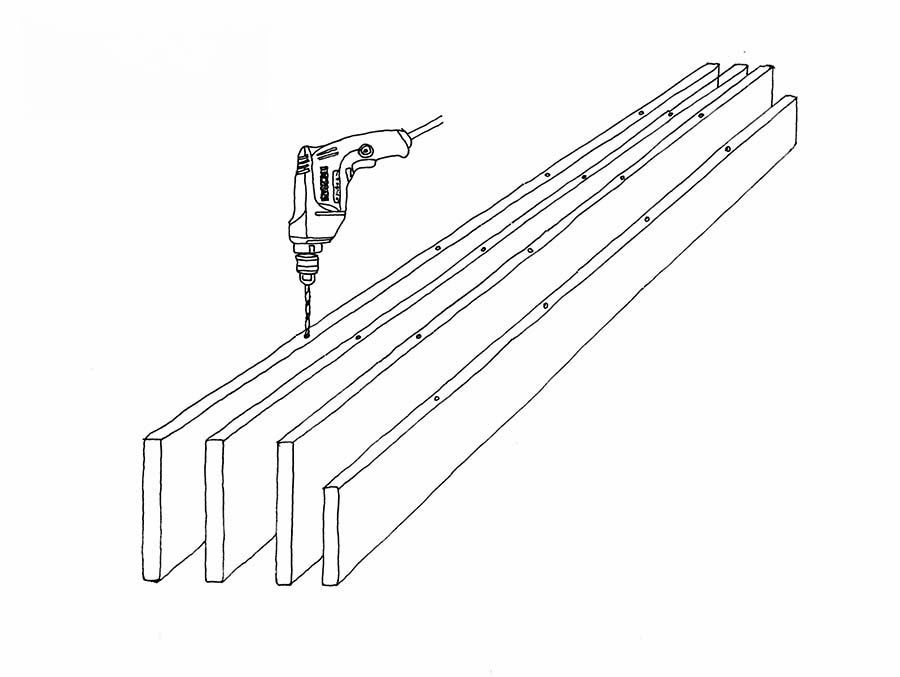

1. Drilling holes in the slats : Saw four pine slats 2500mm long (50mm thick), and use an electric drill to drill a hole every half meter on the side of the slats.

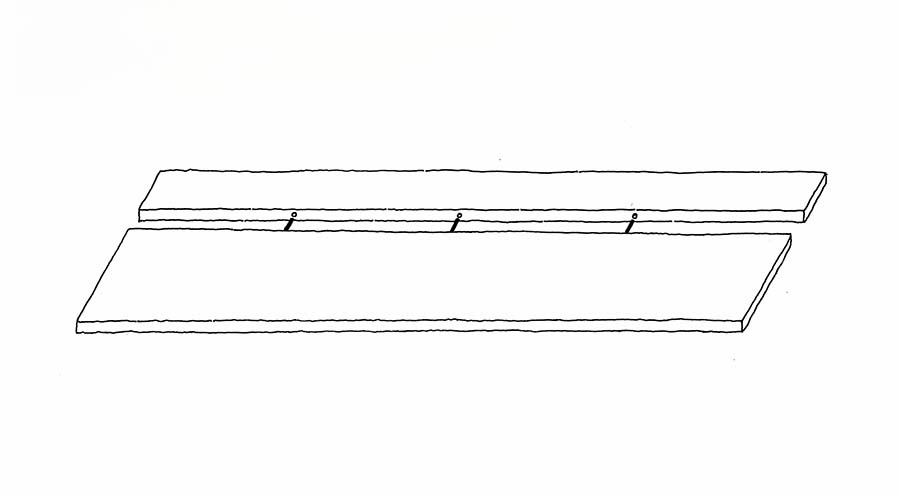

2. Boarding : Brush white glue on the side of the plank, knock the 10mm diameter wooden pins into the side holes of two adjacent planks to connect the planks.

3. Install F clamps : Use four F clamps to clamp the assembled boards for about 24 hours to ensure that the boards are tightly connected.

4. Grinding : Use an angle grinder + impeller to grind the surface of the base plate smooth.

The finished base plate is 2500mm long, 900mm wide and 50mm thick.

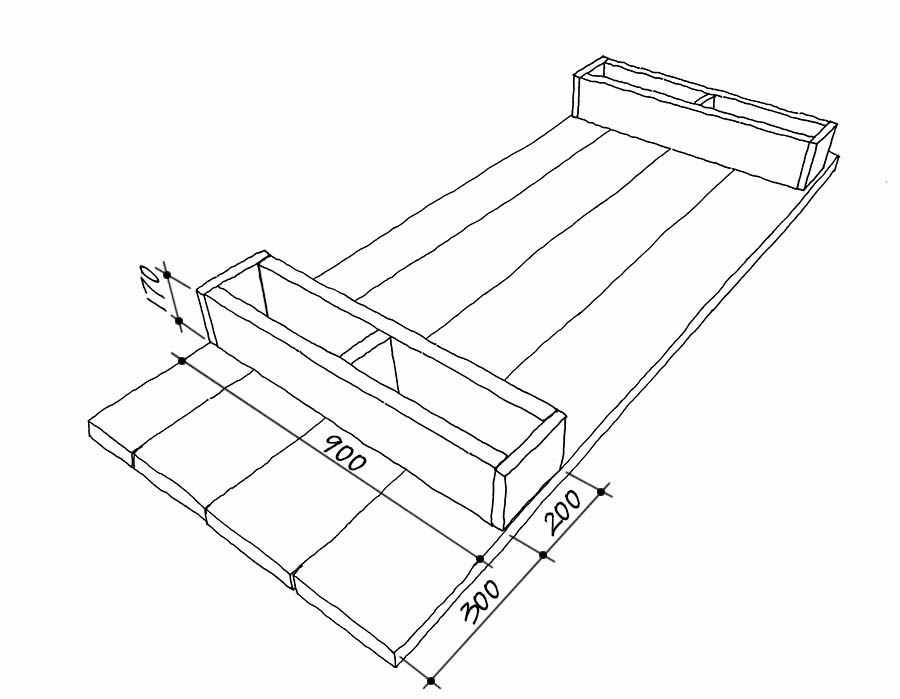

Step 2: Make the Sofa Block

1. Cutting materials : To make a wooden pier, you need two pine wood strips with a length of 850mm, a height of 170mm, and a thickness of 50mm, two pine wood strips with a length of 200mm, a height of 170mm, and a thickness of 25mm, and one pine wood strip with a length of 100mm, a height of 170mm, and a thickness of 25.

2. Connect the wooden pier : Use screws to connect the wooden slats. One wooden pier requires 18 screws. To connect the panels at both ends of the wooden pier, you need to drill countersunk holes on the panels first, then screw in the screws, and then seal the holes with short wooden pins for a more beautiful look.

3. Connect the wooden pier and the base plate : Use screws to connect the wooden pier and the base plate. It is easy to operate and is a favorite for novices.

4. Install plastic spacers and level them : The thickness of the spacers can be adjusted to make the sofa legs level.

Step 3: Make the sofa back

1. Splicing backboard : Two pine boards are spliced into a sofa backboard with a length of 1900mm, a width of 360mm and a thickness of 40mm. The splicing method is the same as the bottom board: white latex + wooden pins + F clamps.

2. Surface roughening : Use an angle grinder + wire brush to roughen one side of the back panel to create convex and concave pine wood grain, blur the seams, and enhance the texture of solid wood. Then, use a scouring pad to polish the surface.

3. Slotting : On the roughened side, use a chisel to cut four grooves with a width of 20mm, a length of 250mm, and a depth of 10mm for installing steel bars.

4. Install the steel bar : Use screws to fix the 20mm wide, 250mm long, and 10mm thick steel bar in the groove of the back panel (when buying the steel bar at the hardware store, ask the boss to drill holes in the steel bar). Since the sofa back panel has to withstand lateral pressure, it needs to be reinforced with steel bars to prevent cracking at the joints.

5. Connect the back panel and the sofa base : Use 6 steel angle brackets to connect the back panel and the sofa base.

Step 4: Apply water-based PU varnish twice

Step 5: Install the sofa cushions

1. Order sofa cushions : Order 3 sofa cushions, 3 back cushions, 2 side cushions and 2 sets of cushion covers online (our family chose 1 set of coffee velvet cover and 1 set of beige linen cover). The sofa cushions cost about 2,000 yuan, and the pine wood and hardware and other expenses were less than 500 yuan. (If you can make sofa cushions yourself, you can greatly reduce the cost.)

2. Fix the Velcro : stick the hook side of the Velcro on the wooden frame of the sofa, and sew the fleece side of the Velcro onto the sofa cover.

3. Install the sofa cushions : Use Velcro to fix the sofa cushions one by one.

4. Matching pillows : Ikea pillows. I hope I can design and make my own pillows in the future.

The sofa back panel is reinforced with steel bars and has a roughened surface.

The holes on the wooden pier panel are sealed with wooden pins.

Steel angle bracket connects the sofa back panel and base.

I want to emphasize that self-made furniture does not mean poor quality . Through reasonable design, self-made furniture can be simple in craftsmanship, genuine in materials, simple and practical, and beautiful in design .