DIY solid wood coffee table, the quality is so high that you can't buy it no matter how much money you spend

After the house is renovated, people will buy furniture for the new house. People also pay more and more attention to quality, especially solid wood furniture, which has become the first choice for new home furniture layout, because solid wood furniture looks more upscale, and secondly, it is more environmentally friendly. However, the disadvantage is that it is expensive. A small coffee table can cost thousands of dollars, which makes many people discouraged.

Today I want to share with you an example of making a coffee table by yourself. The wood is almost all leftovers and the cost is very low. The key is that the coffee table you make by yourself is beautiful, practical, and unique, with an overwhelming sense of quality. You can’t buy it no matter how much money you spend!

Coffee table top production

The coffee table top is not a whole piece of wood, because it is more expensive to use a whole piece of wood. In order to save costs, we splice three pieces of wood together. First, we need to cut and polish each piece of wood for better splicing.

After sanding, use glue to join the three pieces of wood together. After they are completely bonded together, sand the entire thing until the surface is smooth.

Next, we will prepare the tools to make the table top, use the spliced wooden boards to plan out the outline of the coffee table surface, and then hollow out the middle part of the board. This step is the most difficult step in the entire operation process. Everyone should also pay attention during the production process to avoid accidental damage.

Table polishing

After the entire coffee table surface is hollowed out, we need to polish the surface. When polishing, do not cut the coffee table surface from the log, because the whole surface is easier to operate and more convenient to polish.

After the surface of the coffee table is polished, we cut off the entire table top and then polish the edges of the entire table top until the surface is smooth.

After finishing the entire desktop, I felt a little tired, so I went out to breathe some fresh air and then took the dog for a walk.

Coffee table bracket production process

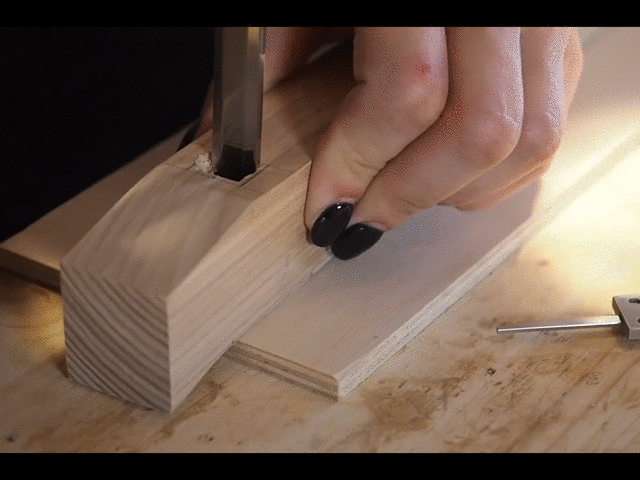

Next, I will introduce the production process of the coffee table bracket. The difficulty in making the bracket lies in the connection point, because the entire coffee table is designed with wood and there are no metal accessories.

First we need to measure and cut the bracket part, and then polish the surface smooth.

Then we debug the tools, adjust them to the best condition, and finally make each component.

In fact, everyone has different methods of furniture making, which requires us to continue to practice and sum up our own set of "practical" experience, so that when our family lacks any furniture, we can do it ourselves.

How about it? Such solid wood rivet parts look really delicate. It is especially important for us to learn how to use tools and use them.

Bracket connection

After the bracket is made, we start connecting it. The connected bracket is so beautiful.

Making of coffee table legs

The table legs are made very simply by making a small hole in the middle of the wooden strip and inserting one end of the bracket into it.

Once the three legs are inserted, the entire coffee table production process is completed.

Surface coloring

In order to make the coffee table more textured, we also need a layer of varnish on the surface of the coffee table, which not only looks good but also can protect the wood material well and achieve the effect of isolating from air.

The tray of the coffee table can be placed on the bracket and used as a small coffee table. We can also take the tray down and place it on the table to use it as a fruit plate, and the bracket can also be used as a flower stand, depending on your mood.

Okay, that’s all I’m going to introduce to you today. If you have any good suggestions, please leave a message below. If you have any ideas, you can also share them with us!