A talented person made his own TV cabinet, sofa and dining table but he doesn't allow them to be posted for fear that others would ask him to make furniture

The talented person made 6 sets of pure ash solid wood furniture for the living room, including "TV cabinet, 3-seater sofa, single sofa, chaise longue and dining table", which took a total of about 16 days.

The total cost of purchasing the above furniture, including wood, tools, paint, sponge and cloth covers, is about 6,000 yuan. A set of pure ash wood furniture for the living room on the market is probably more than 100,000 yuan (think about it, the cheap ones on the market that claim to be ash are basically veneered), isn't it saving a lot, and it is guaranteed to be solid wood, so you don't have to worry about buying veneer or other accessories. Below I will introduce my experience and show my works.

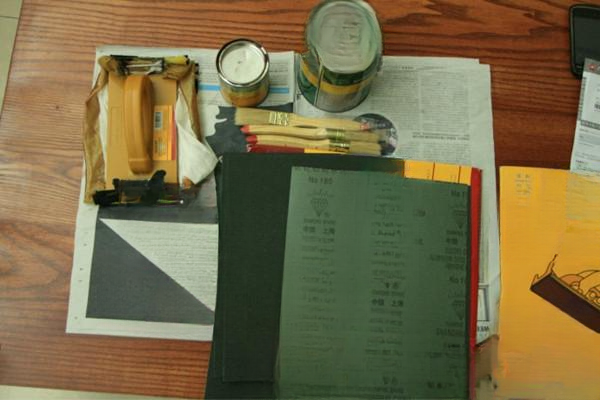

1. Tools include: 1 wood saw, 2 woodworking chisels, 1 square ruler, 1 vernier caliper, 1 wood planer, 1 tape measure, 1 trimming plane, 1 hammer, putty, several pieces of 180 grit sandpaper, several pieces of 240 grit sandpaper, several pieces of 360 grit sandpaper, etc.

2. Production process

1) Once the size and shape of the furniture are designed, as well as the mortise and tenon structure and the physical principles of thermal expansion and contraction, you can start construction.

2) It is recommended to make the coffee table first, because the finished coffee table is like a workbench for making other furniture.

3) The tabletops of coffee tables, dining tables, and TV cabinets should preferably be spliced with boards within 20 cm (using transparent wood glue, such as fish glue). This is to prevent the solid wood from deforming. The recommended thickness of the dining table panel is 5 cm, and the recommended thickness of the coffee table and TV cabinet panel is 2.5 cm.

4) Before sanding each piece of furniture, use putty to fill the gaps in the joints.

5) Detail processing. After the color is applied, the cross-section in the direction of the wood grain is sanded with 240-grit sandpaper to keep the cross-section smooth and the color tone coordinated; secondly, the uneven areas are filled with color with a brush, and then filled again after drying until the original color is coordinated.

6) Apply the top coat. Apply colorless hardwood wax oil, and after 30 to 40 minutes, apply it evenly along the wood grain with a cloth. Apply the hardwood wax oil again after 3 hours. After it is completely dry, polish it with linen cloth (you can also use 2000-grit sandpaper), remember not to penetrate the top coat.

7) Apply clear oil. Use a brush to apply a layer of clear oil, and after 30 to 40 minutes, use a cloth to evenly apply it along the direction of the wood grain.

8) Polishing. Polishing is the last step. Use a fine satin cloth to polish along the direction of the wood grain until you think it feels good.

9) The furniture is done.

10) Finally, I would like to add that when ordering wood, pay attention to the moisture content.

3. Finished product display

This article is compiled and published by Yigao Custom Furniture Editor. If you have read this far, please like, collect, add, and leave! Your support is the editor's greatest motivation!