A complete guide to the basic knowledge of stone, everything you want to know is in it!

Stone Knowledge Encyclopedia

Whether you are a building decorator or a homeowner, stone is an important decorative material and we should all understand its corresponding knowledge and characteristics.

In response to the needs of the majority of netizens, this article will give you some common knowledge about stone, such as: stone types, stone colors, stone characteristics... Everything you want to know is in it, so quickly forward it and collect it~

01

The concept of stone

Stone is a metamorphic or sedimentary carbonate rock. Its main chemical component is calcium carbonate, which accounts for more than 50%, as well as magnesium carbonate, calcium oxide, manganese oxide and silicon dioxide.

02

Classification of stone

American Society for Testing and Materials (ASTM) classification of natural stone

Natural stone refers to materials mined from natural rock and processed into blocks or slabs. The American Society for Testing and Materials (ASTM), the national authority on standards for decorative and finishing materials, has a comprehensive definition and classification of natural facing stone. It has established strict technical standards and specifications for various types of natural stone, and these standards have been recognized and adopted by the vast majority of countries around the world, including the European Union and Japan.

The standard certification of engineering stone materials such as limestone and sandstone is that the National Building Materials Industry Stone Quality Inspection Center directly tests them according to the American ASTM standards.

At present, the American Society for Testing and Materials divides natural facing stones into six categories: granite, limestone, marble, quartz-based sandstone, slate and other stones.

Granite

Definition: A sedimentary rock composed primarily of calcium carbonate (calcite mineral) or calcium magnesium carbonate (dolomite mineral), or a mixture of the two minerals. Commercially, there are the following types of limestone: calcite, shell limestone, dolomite, microcrystalline limestone, calcite, recrystallized limestone, and tuff.

Performance classification:

Low-density limestone has a density ranging from 1.76 to 2.16 g/cm3.

Medium-density limestone has a density ranging from 1.76 to 2.56 g/cm3.

High-density limestone, with a density above 2.56g/cm3

Marble

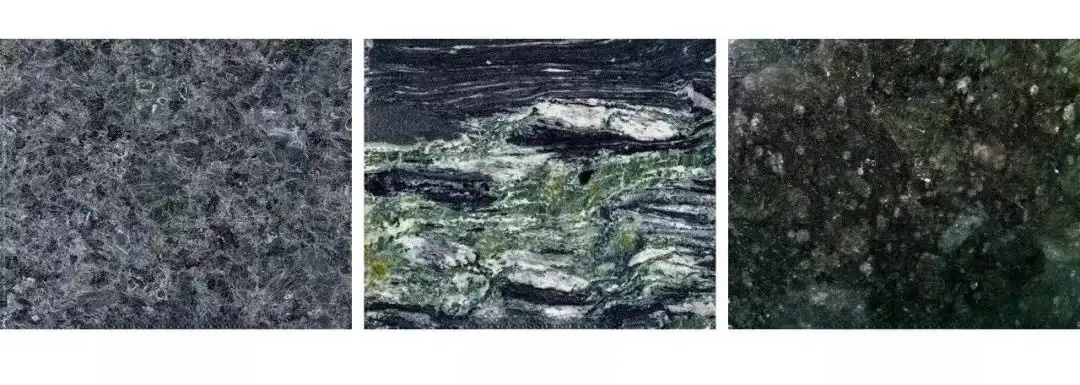

Definition: This type of stone must be polishable and has a wide range of composition and texture types, ranging from pure carbonate to rocks with very low carbonate content, collectively known commercially as marble. Most of them have patterns or veins, and the crystal grain size ranges from cryptocrystalline to 5mm in diameter.

Classification:

Commercially, it is mainly divided into calcite marble, dolomite marble, agate striped marble, serpentine marble, tuff marble, etc.

Calcite marble: mainly composed of calcite, with a unique crystal structure formed due to recrystallization.

Dolomite marble: It is mainly composed of dolomite, which has a crystalline structure formed through high temperature and pressure during the metamorphic period.

Serpentine marble: mainly composed of serpentine (magnesium silicate hydrate), green or dark green, with veins composed of dolomite, calcite or magnesite.

Tuff marble: A porous, layered structure of tuff containing some calcite crystals.

Limestone

Definition: A granular igneous rock, usually pink to light or dark gray, composed primarily of quartz and feldspar with minor amounts of black minerals, with a uniform grain texture, sometimes showing a gneissic or porphyry structure.

Sandstone (Quartz-based)

Definition: A type of sedimentary rock composed primarily of mineral and rock particles (0.06-2 mm in size) containing at least 60% silicon dioxide. It has a porous structure composed of silica, iron oxide, carbonates, or clay.

Classification:

Commercially, it is mainly divided into blue-gray sandstone, brown sandstone, orthoquartz sandstone, quartzite, gravel, and siltstone.

Sandstone: Silica content is 60-90%.

Orthoquartz: The silicon dioxide content is 90-95%.

Quartzite: The silica content is above 95%.

Slate

Definition: A microcrystalline metamorphic rock, typically derived from shale, composed primarily of mica, oxynitrides, and quartz. Slate contains mica minerals that strike approximately parallel to the bedding plane and can be cleaved along the bedding plane to form thin, hard slabs.

Other stones

Semi-precious stones, such as jade, semi-precious stones, shells, agates, gemstones, and crystals, are sometimes used as facing stones. Generally, the amount used is not large, just for embellishment.

03

Stone formation

Natural stone is mined from natural rock and processed into blocks or slabs.

Marble and granite are the two most commonly used types of stone. Marble is a metamorphic carbonate rock formed from pre-existing rocks in the Earth's crust through sedimentation or high temperature and high pressure. Its primary component is calcium carbonate, which accounts for over 50%. Because marble generally contains impurities, such as large crystals, it is brittle. Furthermore, calcium carbonate is susceptible to weathering and dissolution in the atmosphere due to carbon dioxide, carbides, and moisture, causing the surface to lose its luster. Of course, you don't need to worry about this, as geological ages are measured in billions of years, and this qualitative change is limited within our lifetimes.

Granite is a rock formed by the crystallization of underground magma or volcanic lava. Its main component is silicon dioxide. When the content exceeds 65%, it is considered acidic rock. This rock is composed of crystals of basic minerals such as feldspar, quartz, and mica. It has a granular structure and is hard and dense. Therefore, granite is often used outdoors and in relatively harsh environments.

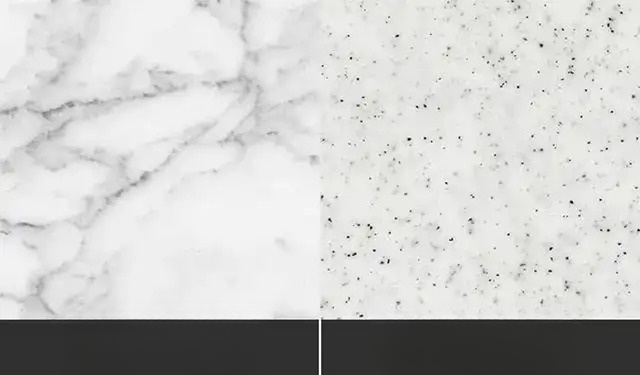

The natural stones sold on the market today are not classified so finely. Most of the time, carbonized stones with textures are called marble, and those with spotted crystalline particles are called granite. Of course, such detailed classification is not necessary for interior decoration.

Another point worth mentioning is that natural stone contains radioactive substances. Rest assured, natural stone, like any other substance, contains radioactive elements, but the concentration is very low and does not pose a risk to humans. Currently, only granite on the market has a clear definition of radioactivity, classified as A, B, and C. Most stone meets the Class A standard.

Under normal circumstances, the radioactivity of stone can be determined by its color, which, from highest to lowest, is red, green, flesh-red, off-white, white, and black. Granite generally has a higher radioactivity than marble. When purchasing, pay attention to whether the stone has been artificially treated. This type of stone will have a poor surface gloss and unnatural color. A poorly treated stone will have a large contrast between the cross-section and the surface color, appearing somewhat whitish. It will also have a slightly lower hardness and will generally show its true color after six months to a year of use. Good stone will have a mirror-like luster and clearly reflect the scenery.

Also, check if there is a grid on the back of the stone. This type of stone is brittle and has been treated to increase its hardness. Try to choose stone that meets Class A standards. The load-bearing thickness should not be less than 15 mm. The thickness should be uniform and free of pits. The four corners should be accurately defined, and the cut edges should be neat and free of cracks.

04

Mineral composition of stone

As we all know, stone is made from rocks taken from mines and processed by humans. Rocks are composed of various minerals.

Minerals are relatively stable natural products formed by various chemical elements in the earth's crust through various geological processes. The minerals in stone are shown in the table below.

05

Selection of stone

When choosing stone, you can select the material according to its characteristics and color.

Cabinet countertops, door sills, and stair steps are mainly made of granite. The rock hardness should be denser, the color should be darker, and the color difference should be small. Dark colors are often chosen because they are easier to clean and have a more layered feel without making people feel light and airy.

Marble can be used for bay window countertops, decorative walls, and bathroom countertops. Compared to granite, marble is softer in hardness, has a variety of colors, and has beautiful textures. If you choose a light-colored bay window, it can give people a warm and quiet feeling and also visually expand the area of the window sill.

If you want to decorate the wall, you can choose travertine, a type of marble. It comes in beige and white, and is elegant and simple.

06

The criteria for judging the quality of stone

The types of stone are generally classified according to their color, pattern and other characteristics as well as their origin and purpose.

Natural decorative stone is made from natural stone, so its quality depends on the quality of the raw material and the processing process. The main manifestations of poor quality stone are as follows:

(1) Surface pattern and color.

When it comes to decorative stone, people primarily value the decorative effect of its processed surface. High-quality stone can have patterns and colors that are beautiful and elegant, elegant and luxurious, resembling flowing clouds and water, or sparkling like stars, creating a superb decorative effect. However, inferior stone, after processing, has unattractive patterns and colors, failing to offer aesthetic enjoyment.

Therefore, the color and pattern of the stone surface are the main indicators for evaluating the quality of the stone. As mentioned above, the colorful marble produced in Dali, Yunnan, is the best marble because of its rare color and pattern.

(2) Appearance quality of the plate after processing (processing quality).

The surface characteristics of natural stone emerge through processes such as cutting, sawing, grinding, and polishing. This processing can leave some surface defects (for example, marble slabs may have warping, cracks, pinholes, dents, stains, blemishes, and missing edges and corners; granite slabs may have missing edges, missing corners, cracks, stains, color lines, and pits). If these defects exceed the limits specified by national standards, the stone will be considered unqualified.

If these inferior slabs with poor appearance quality are used for surface decoration, the overall decorative effect will not be satisfactory. Therefore, when judging the quality of stone, in addition to considering the pattern and color, it is also necessary to check its processing quality.

(3) Deviation of specification dimensions (processing dimensions).

Large decorative stones are processed into slabs. During construction, they are either laid (for floors) or tiled (for walls). To ensure a smooth decorative surface and neat seams, national standards stipulate the tolerances for the length, width, and thickness of the slabs, as well as the maximum tolerances for the surface flatness, front and side angles. Substandard slabs are processed with poor precision.

This causes dimensional deviations beyond the specified range of national standards. After paving, these slabs will have uneven surfaces and uneven seams. This can create irregular lines on facades, affecting the overall decorative effect. Therefore, dimensional deviations directly impact the performance of the stone.

(4) Physical and chemical performance indicators.

Stone used for decoration is often selected based on its decorative properties (i.e. the color, pattern, glossiness and appearance quality of the stone surface). However, when evaluating the quality of stone, in addition to considering the decorative properties, other quality indicators should also be considered, such as compressive strength, flexural strength, durability, frost resistance, wear resistance, hardness, etc.

These stones with excellent physical and chemical properties can effectively resist the influence of various external factors during use, ensuring the decorative effect and service life of the stone decorative surface.

On the contrary, inferior stone has poor physical and chemical properties and cannot guarantee the durability of stone decorative surfaces. In short, when evaluating the quality of stone, we should not be limited to one aspect, but should evaluate it as a whole, considering both its decorative properties and its performance.

07

When to install stone

After the ground is leveled, the threshold stone can be installed together with the floor tiles. The bay window can be installed before the wall is leveled to fill the gap and will not dirty the wall. The steps can be installed after the floor tiles are installed, and there will be no gap between the tiles and the steps. The decorative walls, bathroom countertops, and cabinet countertops depend on the progress of the decoration company's base work.

08

Stone installation precautions

(1) When installing light-colored stone, the owner needs to prepare white cement and river sand; dark-colored stone can use ordinary cement; if it is laid directly on the wooden base, the owner also needs to prepare glass glue;

(2) Door cutouts are best installed together with floor tiles, or before door moldings. Window sills can be installed before the last coat of putty, and basins and stoves can be installed a little further back.

(3) Stone is usually installed by the manufacturer.

The details are as follows

1. Floor stone installation:

When installing floor stones, pay attention to the glue mesh on the back of the stone. If the glue mesh is torn off, the stone will be easily damaged during construction and the cement slurry will seep out of the stone reinforcement to the surface, which will appear to be broken at first glance. If the glue mesh is not torn off, two days after construction, knocking on the stone with metal will make a sound similar to a hollow drum.

Solution: If the glue mesh is tightly bonded to the back of the stone, it is recommended to continue with the installation. If the glue mesh is loosely bonded to the stone, it is recommended to remove the glue mesh before installation. If the slurry seeps out of the stone surface, gently scrape it off with a wallpaper blade after two days.

Construction precautions:

A. Beige and white stone construction: Use black cement for the mortar mixture, and white cement for the back of the stone. For dark-colored stone, use black cement.

B The cement mixture is dry and hard cement mortar (can be kneaded into a ball), and the back of the stone is covered with 5mm thick pure cement mortar; it is strictly forbidden to use the grouting method (pouring pure cement slurry water on the mixture).

C Before marble construction, layout, color, and grain matching should be done indoors, with the main large areas determined first, followed by the secondary areas, as natural stone has different colors and grains.

D. Stone grouting: Use black cement for dark-colored materials and white cement or white cement mixed with corresponding pigment powder for light-colored materials. Do not use marble glue for grouting to prevent contamination of the board surface.

E After the stone is installed, mirror protection can be used to prevent erosion and corrosion by oil stains, acid and alkali liquids.

2. Wall stone installation

When installing stone on indoor walls, try to avoid grouting (except for dark stone). This is because the stone surface will have different shades of color due to different water absorption rates, and rust spots may appear on the surface of white materials.

Wall stone installation method (for indoor use only):

A. Construction with tile adhesive: scrape the adhesive all over (zigzag shape) on the back of the stone or lay 5 points on the back of the stone, and stick the stone directly on the wall painted with cement mortar.

B If the wall base is wood board, use stone AB glue (do not use marble glue) as the adhesive between the wood board and the stone, then groove the stone in the width direction, and use 18# copper wire to connect the stone with the self-tapping screws on the wood board.

C If the wall base is concrete or standard brick wall rather than porous bricks or aerated bricks, a simple dry hanging method should be used for construction.

3. Countertop Stone Installation

When installing the countertop, please note that the lower water retaining plate of the countertop cannot be fixed with glue, because the glue has a "lifespan" and is in contact with liquid for a long time. Once it fails, the lower water retaining plate may fall off and injure people.

Solution: Use a combination of glue and stainless steel hangers. The weight of the lower water retaining plate should be transferred to the steel frame through the hangers. After the countertop is installed, the stone and basin must be sealed with weather-resistant glue to prevent the marble glue from becoming ineffective due to long-term water exposure.

09

Stone maintenance and care

1. All stone materials are sensitive to acids and alkalis, which can cause granite to yellow and marble to erode. Alkali can also cause granite crystals to flake off, causing the stone surface to lose its luster. A neutral pH cleaning agent should be used. Mild soap and water are all that's needed for daily granite cleaning.

2. The surface of the stone should not be covered with carpets and debris for a long time. Keep the stone breathing smoothly. Otherwise, the stone will become diseased due to excessive moisture and increased water content. If carpets are laid or debris is piled up, they need to be changed frequently.

3. Keep the environment ventilated and dry. Stone is afraid of too much humidity. Water vapor will hydrate, hydrolyze and carbonate the stone, causing water spots, whitening, weathering, erosion, rust and other diseases.

4. Try to avoid direct and frequent friction between the soles of your shoes and the ground. It is best to change into slippers after entering the house to reduce the chance of sand and dust wearing the stone surface.

5. If any contaminant (oil, tea, coffee, cola, soy sauce, ink, etc.) is spilled on the stone, it must be cleaned immediately to prevent it from seeping into the pores. All stones have natural pores, and if not handled promptly, dirt can easily penetrate through the pores into the stone, forming unpleasant stains.

6. Do a good job of maintenance. You can use some quality-guaranteed waterproofing agents appropriately, and do not wax casually. There are many types of wax on the market, including water-based wax, stearic acid wax, oil-based wax, acrylic wax, etc. These waxes basically contain acid and alkaline substances, which will clog the pores and also be stained with dust to form wax scale, causing yellowing on the stone surface.

Moreover, wax contains ammonia, which will cause adverse effects on the human body and the environment after volatilization and decomposition. Currently, crystal surface treatment is the best maintenance method.

10

Common terms for stone

Special-shaped stone: generally refers to the general term for stone products other than rectangular and square slabs.

Facing stone: stone used to process veneer panels.

Bamboo leaf limestone: limestone composed of round and oval fan-flat gravels arranged in parallel. The shape of the gravels on the vertical section resembles bamboo leaves.

Rough material: irregularly shaped stone separated directly from the mine.

Rough stone: Stone processed from raw materials with certain specifications and used to make decorative panels.

Standard material: rough material that meets standard specifications.

Rough board: a board sawn from rough materials.

Axe-cut board: refers to the rough surface decorative panel processed with an axe.

Hammered board: refers to the rough surface decorative panel processed with a flower hammer.

Singeing board: refers to the rough surface decorative panel processed by flame method.

Fine panel (polished board): a board with a flat and smooth surface.

Mirror plate (polished plate): a plate with a smooth surface and mirror gloss.

Color spots and lines: striped, striped or spotted substances that are not in harmony with the basic color and pattern of the facing stone.

Sawing: The process of processing rough materials into rough boards.

Polishing: The process of processing the surface of the rough board into a flat and smooth one.

Polishing: The process of processing the surface of a fine panel to have a mirror-like gloss.

11

Calculation method of stone

(1) Domestic stone materials are mostly of fixed size with width of 60, 70, and 80 cm, and the price is calculated by the meter;

(2) Most imported stones are large and priced by square meter. (However, some imported granites are also priced by meter, such as imported black gold sand.)

(3) If the window sill or the place where the stone is to be installed is of an irregular shape (such as diamond, triangle, circle, etc.), the material consumption is calculated based on (longest × widest). If the double sides are ground, a loss of 3 cm should be added, which should be larger than the actual size;

(4) The cost of stone materials consists of several parts: material cost + processing fee (grinding, cutting corners, digging holes, hanging edges) + installation fee + transportation fee + upstairs fee.

12

Marble resource status

world

The world's natural marble production, measured in terms of rough block production, was 25.35 million tons in 1990, 34 million tons in 1993, 39 million tons in 1995, and 45.7 million tons in 1997. These figures indicate that stone production in 1997 was 1.8 times that of 1990, a significant increase compared to other industries.

European stone production has always been in a leading position in the world, but its output as a proportion of the world's total output has dropped from 77% in the past to 52.6% in 1997.

Italy's annual stone production remained between 7.2 and 7.5 million tons between 1990 and 1997, maintaining its position as the world's largest stone producer. However, its share of the world's total stone production has been declining. For example, in the mid-1980s, it accounted for about 30%, but by the end of the 1980s, it accounted for 25%, and in 1994, it accounted for 19.8%, and in 1997, it fell to 16.4%.

Asia has been the most active region for marble mining since 2000. Firstly, its natural marble industry has experienced rapid development since the reform and opening up, with approximately 27,000 stone material enterprises and 5 million employees.

Stone resources are found throughout China, both north and south of the Yangtze River, and both inside and outside the Great Wall. Stone resources are developed in over 30 provinces, municipalities, and autonomous regions. From Mongolian Black in Inner Mongolia to Yazhou Red in Hainan Province; from Dandong Green in Liaoning to Tianshan Blue in Xinjiang, the vast stone reserves are plentiful, and the famous and special varieties rank among the best in the world.

There are over 3,000 mining sites nationwide, producing over 1,000 varieties of granite. Developed granite resources are primarily concentrated in coastal provinces. Five provinces and autonomous regions—Shandong, Zhejiang, Fujian, Guangdong, and Guangxi—account for nearly 70% of China's total granite production.

13

Industrial technical requirements for marble

The industrial technology requirements for natural marble have different emphases due to different applications.

Main requirements for natural marble blocks

The blocks must be in the shape of a rectangular parallelepiped. The block dimensions must be greater than or equal to 100 cm in length, greater than or equal to 50 cm in width, and greater than or equal to 70 cm in height. The appearance quality requirements are that the color and pattern of blocks within a batch should be essentially consistent. The appearance quality grade for missing corners, edges, and cracks in the blocks must comply with the requirements in Table 4.25.6.

Physical performance requirements: bulk density not less than 2.6g/cm3; water absorption not greater than 0.75%; dry compressive strength not less than 20MPa; flexural strength not less than 7.0MPa.

Quality requirements for marble for craft carving

The marble must have a dense structure, uniform particles that are not easily detached, no cracks, no inclusions, and its color, pattern, size, and shape must meet the requirements of the model. Generally, it must be larger than 0.15m3. If used outdoors, the rock surface does not need to be fresh, but it must have good weathering resistance and low water absorption.

Quality requirements for electrical insulation boards

The physical and electrical properties of marble electrical insulation boards shall meet the requirements of Table 4.25.7.

Many nonferrous metals, rare metals, precious metals, and non-metallic minerals are genetically related to marble. Marble itself is also an excellent building material and raw material for arts and crafts. Marble is not very hard, belonging to the medium-hardness category, making it easy to mine and process.

After polishing, the board presents decorative patterns or color textures, which are very beautiful and can be used as indoor and outdoor decoration materials. Because marble is basically composed of pure calcium carbonate or magnesium carbonate.

Therefore, it is extremely sensitive to the dissolution of acid-polluted air. Urban atmosphere usually contains carbonic acid separated from carbon dioxide and sulfuric acid generated from smoke. These substances are constantly in contact with marble, causing marble products to be affected to varying degrees. In any case, marble is still an ideal material for architectural decoration and sculpture.

14

The difference between natural marble and artificial marble

Artificial marble is made of unsaturated polyester resin as a binder, mixed with natural marble or inorganic powders such as calcite, dolomite, silica sand, glass powder, and appropriate amounts of flame retardants and colors. It is formed and solidified through methods such as mixing, porcelain casting, vibration compression, and extrusion.

Artificial marble was developed based on the problems encountered in the actual use of natural stone. It has made great progress in moisture resistance, acid resistance, high temperature resistance and splicing properties.

Of course, man-made things naturally have their own shortcomings. Artificial stone is generally less natural and has a relatively fake texture, so it is mostly used in places with high practical requirements such as cabinets, as well as in some harsh environments such as kitchens and bathrooms; it is less used in places that emphasize decorativeness, such as window sills and floors.

Another factor that hinders the use of artificial marble is the human factor. Since the production process of artificial stone varies greatly, the performance and characteristics are not completely consistent. Therefore, the advantages mentioned above are not necessarily the performance of the artificial stone purchased by the user.

15

Difference Between Marble and Granite

Natural marble is a metamorphic rock formed from pre-existing rocks in the Earth's crust through high temperatures and high pressures. It is a medium-hard stone composed primarily of calcite, limestone, serpentine, and dolomite. Its primary component is calcium carbonate, which accounts for over 50%. Other components include magnesium carbonate, calcium oxide, manganese oxide, and silicon dioxide.

Because marble generally contains impurities, and calcium carbonate is easily weathered and dissolved by carbon dioxide, carbides, and moisture in the atmosphere, causing the surface to quickly lose its luster. Therefore, a few pure, impurity-free, stable and durable varieties, such as white marble and wormwood green, can be used outdoors. Other varieties are not suitable for outdoor use and are generally only used for interior decorative surfaces.

Natural marble can be made into decorative panels for high-end decorative projects. It is used for interior walls, facades, railings, floors, window sills, service counters, and elevator door surfaces in public buildings such as hotels, exhibition halls, theaters, shopping malls, libraries, airports, and train stations. It is an ideal high-end indoor decorative material. It can also be used to create marble murals, handicrafts, and daily necessities.

Natural granite is an igneous rock, also known as acidic crystalline plutonic rock. It is the most widely distributed type of igneous rock and is a hard stone composed of feldspar, quartz, and mica. Silicon dioxide accounts for approximately 65% to 75% of its composition. The rock is hard and dense, and can be divided into three types based on its crystal grain size: pegmatite, coarse-grained, and fine-grained.

The quality of granite is determined by its mineral composition and structure. High-quality granite features fine and uniform crystal grains, a low mica content and a high quartz content, and is free of pyrite. Granite is resistant to weathering and deterioration, retaining its lustre for over a century. Therefore, it is often used for wall foundations and exterior wall cladding. Due to its high hardness and wear resistance, granite is also commonly used in high-end architectural renovation projects, such as lobby floors.

Because granite is harder and more acid-resistant than marble, it is more suitable for outdoor balconies, courtyards, living and dining room floors and window sills in home decoration. Marble can be used for bar counters, cooking tables, and dining cabinets.

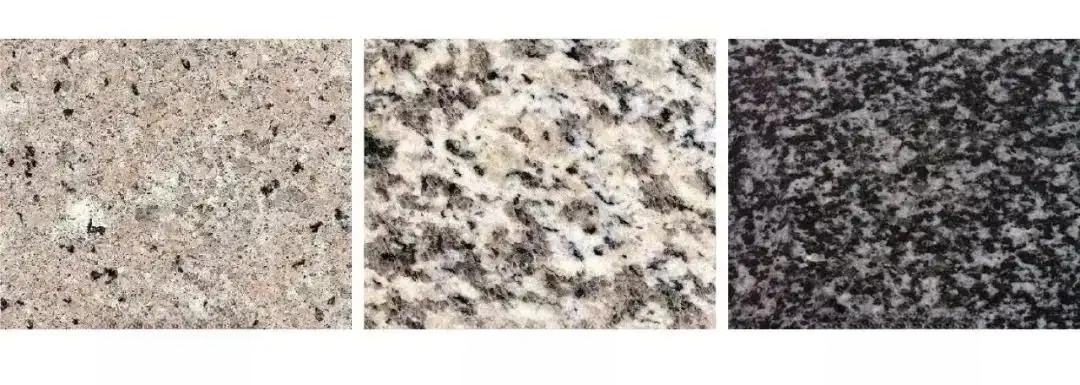

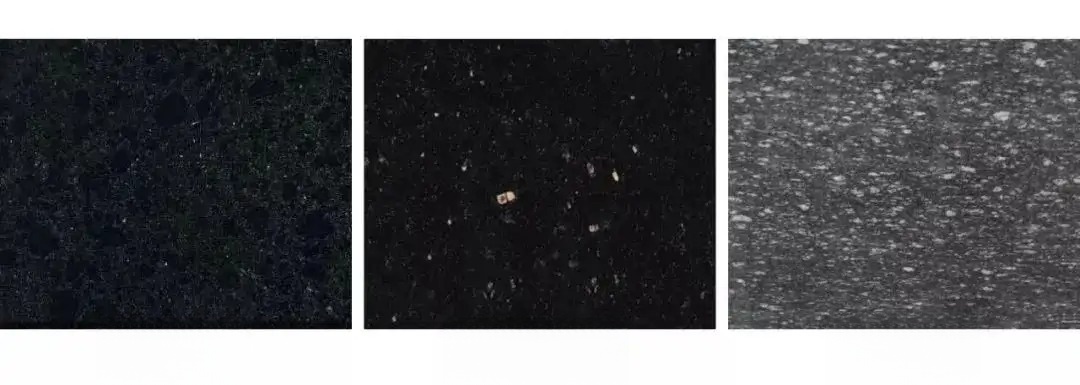

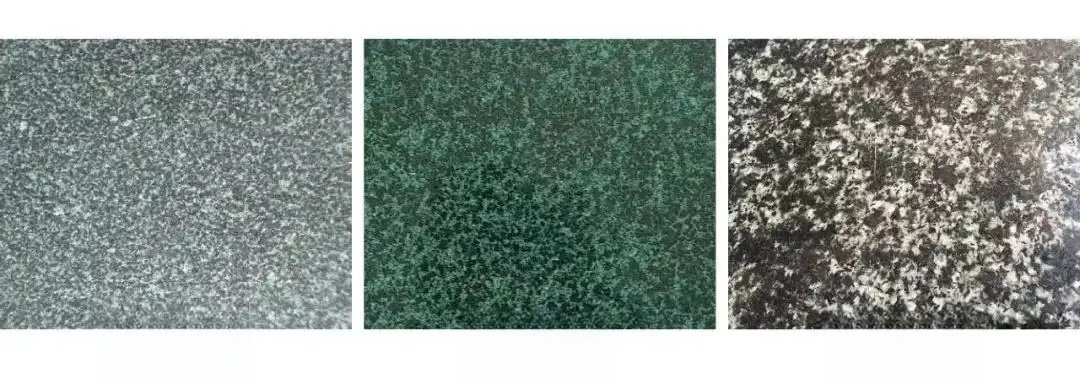

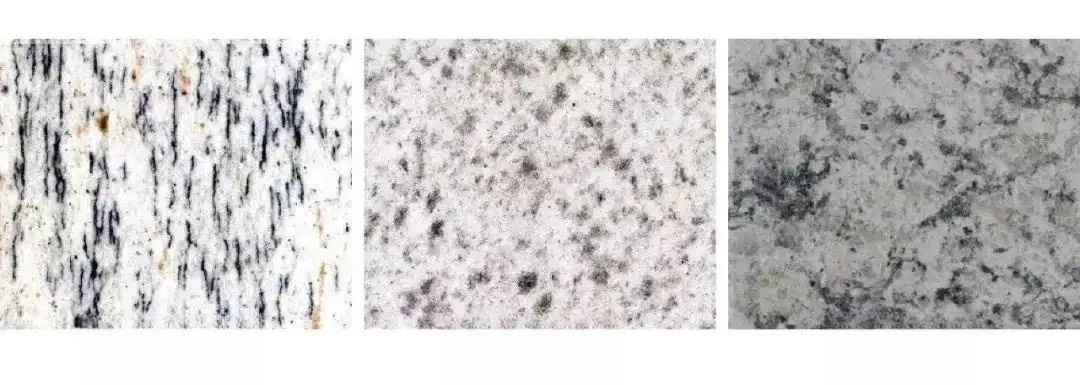

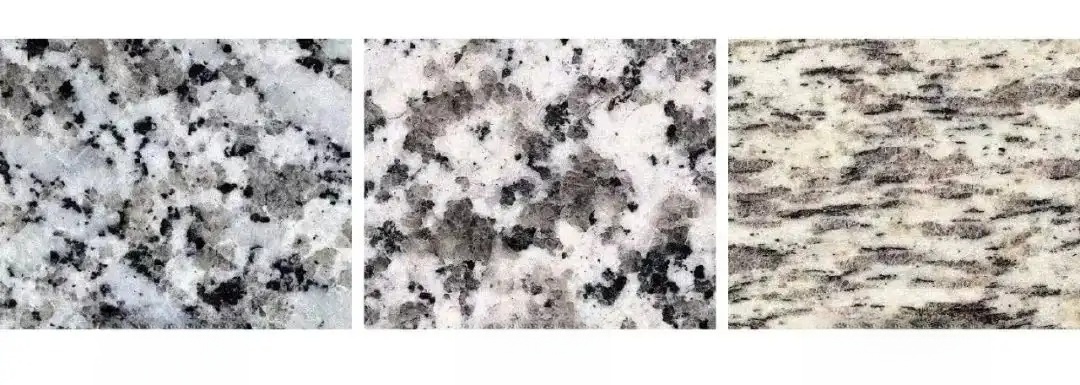

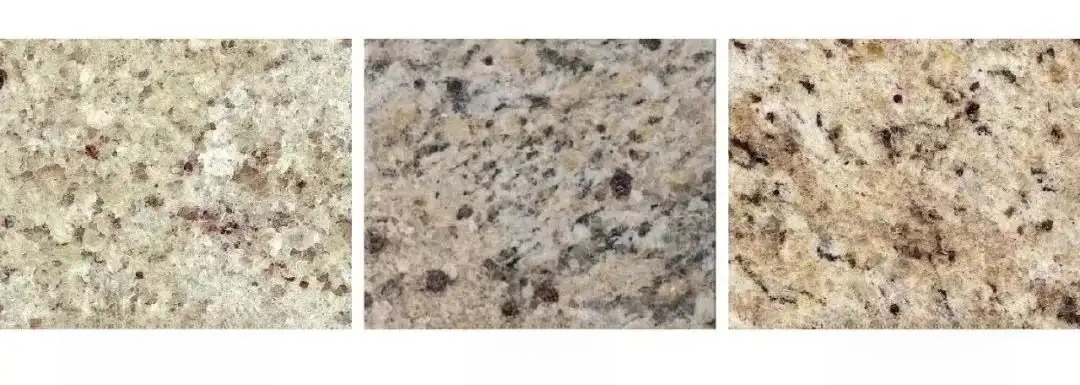

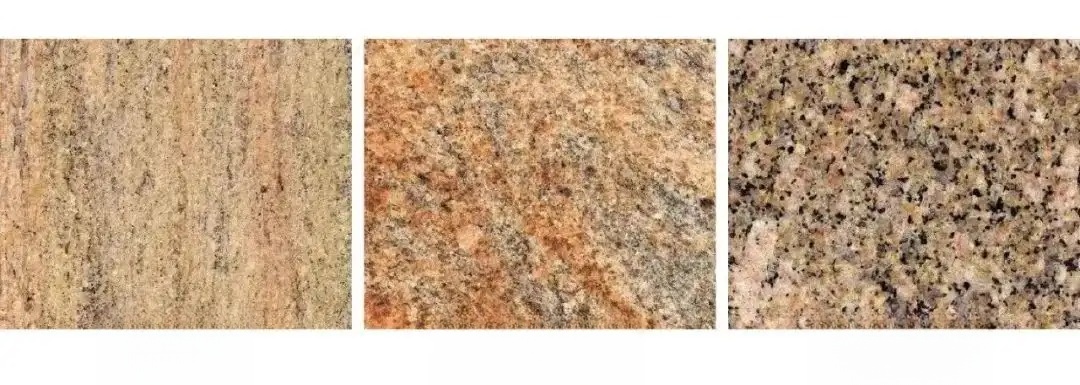

1. Granite: Granite has no color stripes. Most of them have only color spots, and some are pure colors. The finer the mineral particles, the better, indicating a dense and solid structure.

2. Marble: Marble has a simple mineral composition and is easy to process. Most marble slabs have a fine texture and a good mirror finish. However, its disadvantages are that it is softer than granite, easily damaged by impacts from hard objects, and light-colored stone is easily stained. For flooring, choose a solid color. For countertops, striped slabs work best. For other selection methods, refer to the granite selection guide.

16

Radiation problems of marble

According to the>

20

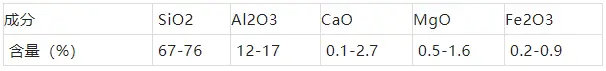

Composition of granite

Granite is formed by igneous rock. It is a steel-hard crystalline stone. It is originally formed by feldspar and quartz and is mixed with one or more black minerals. It is arranged flat in structure.

Granite is primarily composed of quartz, feldspar, and mica. Feldspar accounts for 40%-60% and quartz 20%-40%. Its color depends on the type and amount of these components. Granite is a fully crystalline rock. High-quality granite features fine and uniform grains, a dense structure, a high quartz content, and a bright feldspar sheen.

Granite has a high silica content and is classified as acidic. Some granites contain trace amounts of radioactive elements and should not be used indoors. However, granite has a dense structure, a hard texture, and is resistant to acids, alkalis, and weathering, making it suitable for long-term outdoor use.

21

Properties of granite

Physical properties

Huayan is a unique material, and its physical characteristics are mainly as follows:

Porosity/Permeability: The physical permeability of granite is almost negligible, ranging from 0.2% to 4%.

Thermal stability: Granite has high thermal stability and will not change due to changes in external temperature. Granite has a high density and will not change due to changes in temperature and air composition. Granite has strong corrosion resistance and is therefore widely used in the storage of chemical corrosives.

Ductility: The ductility coefficient of granite ranges from 4.7x10-6 to 9.0x10-6 (inch x inch).

Color: The color and texture of granite are highly consistent.

Hardness: Granite is the hardest building material, and its extreme hardness also makes it very wear-resistant.

Composition: Granite is primarily composed of quartz, orthoclase, and microcline. The most primitive granite is primarily composed of the following three components: feldspar, quartz, and biotite. The proportions of each component are generally determined by color and material, but generally feldspar accounts for 65%-90%, quartz 10%-60%, and biotite 10%-15%.

Chemical properties

Granite is mainly composed of feldspar, quartz, and biotite, but it is also accompanied by the presence of other minerals. The main proportions of various minerals are as follows:

22

Classification of granite

Granite has many types and can be classified in many ways due to its complex composition and diverse formation conditions.

According to the types of minerals contained

It is divided into black granite, muscovite granite, hornblende granite, two-mica granite, etc.

According to structural structure

It can be divided into fine-grained granite, medium-grained granite, coarse-grained granite, porphyritic granite, porphyritic-like granite, geode granite and gneissic granite.

According to the accessory minerals

It can be divided into cassiterite granite, niobite granite, beryllium granite, lepidolite granite, tourmaline granite, etc. Common automorphisms include feldsparization, greisenization, and tourmalineization.

23

Characteristics of granite

Granite has a dense structure, high compressive strength, low water absorption, high surface hardness, good chemical stability, and strong durability, but poor fire resistance.

Granite has a granular structure of fine, medium, or coarse grains, or a porphyritic structure. Its grains are uniform and fine, with small gaps (porosity is generally 0.3% to 0.7%), low water absorption (water absorption is generally 0.15% to 0.46%), and good frost resistance.

Granite is known for its high hardness, with a Mohs hardness of around 6. Its density ranges from 2.63 g/cm³ to 2.75 g/cm³, and its compressive strength ranges from 100 to 300 MPa, with fine-grained granite reaching over 300 MPa. Its flexural strength is generally between 10 and 30 MPa. Granite is often found in the form of bedrock, stocks, and blocks, and is controlled by regional tectonic shifts. It is generally large and widely distributed, making it easy to mine and produce large pieces. Its well-developed joints also facilitate the extraction of regularly shaped rocks.

Granite has a high yield rate, is amenable to various processing methods, and offers excellent slab splicing properties. Furthermore, it resists weathering and can be used as outdoor decorative stone. Granite has a uniform texture and, while primarily pale in color, also offers a wide variety of colors, including red, white, yellow, green, black, purple, brown, beige, and blue. Its color variation is relatively minimal, making it suitable for large-scale applications.

24

Characteristics of granite

Granite is beautiful, durable and very hard. In ancient times, if there were advanced mining and processing equipment and technology, it would definitely be more popular than marble.

Granite often contains other minerals such as amphibole and mica, resulting in a variety of colors including brown, green, red and the common black.

Because it crystallizes slowly, its crystals intertwine like a Rubik's Cube, making it incredibly hard. It's as durable as a house, resisting chipping, scratching, and high temperatures. Regardless of color or finish, with common sense care, it won't fade or darken. It's virtually impervious to contamination, achieving a high gloss after polishing, and virtually resistant to weather-related impurities.

Granite is typically mined using wire rope sawing. Newer techniques, such as dense drilling and flame spraying, have emerged. Flame spraying produces clean cuts, no hidden defects, and high production efficiency. After roughing, the mined stone is called rough material. It is then manually drilled and chiseled or machine sawed to produce blocks or slabs of the desired size. Milling machines or lathes are used to form cylindrical or curved shapes. Finally, coarse and fine rock-like grains are manually chiseled, or machine-ground and polished to a crystal-clear finish.

Granite is environmentally friendly. Synthetic materials often leave unpleasant or even toxic byproducts and need to be replaced several times during the life of the building (each time with associated disposal issues). Granite doesn't need to be replaced because it's incredibly durable.

In addition, granite is very practical and can be made into a variety of surfaces - polished, matte, fine-ground, flamed, water-jet treated and sandblasted. Because granite often contains radioactive substances, when using granite, its radiation level needs to be measured and then its use occasion needs to be confirmed.

25

Types of granite

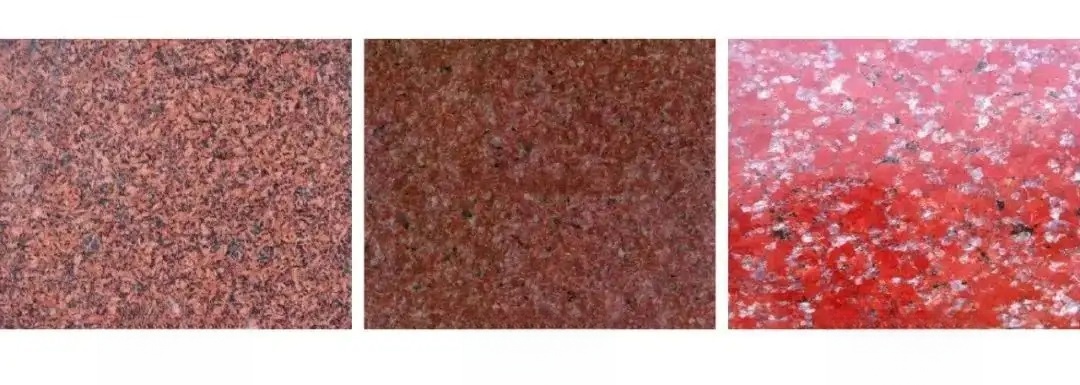

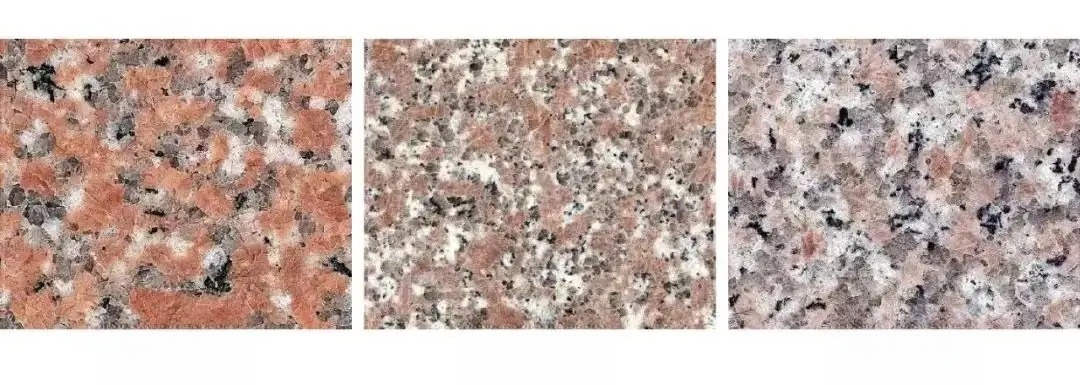

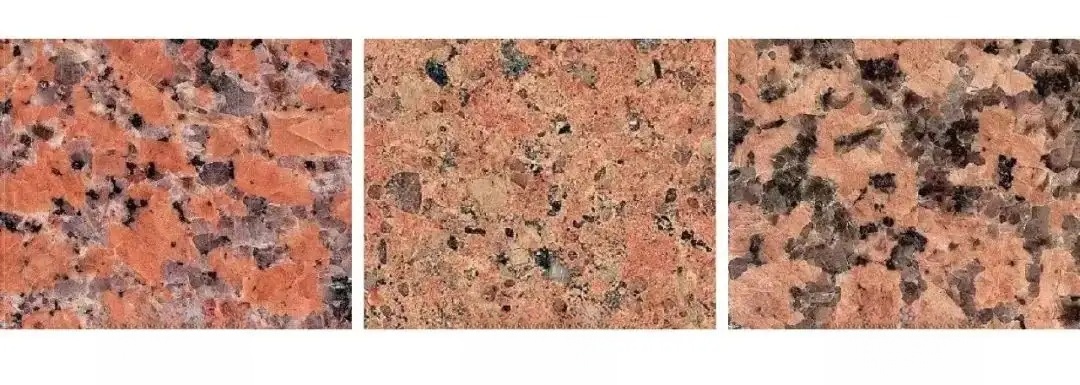

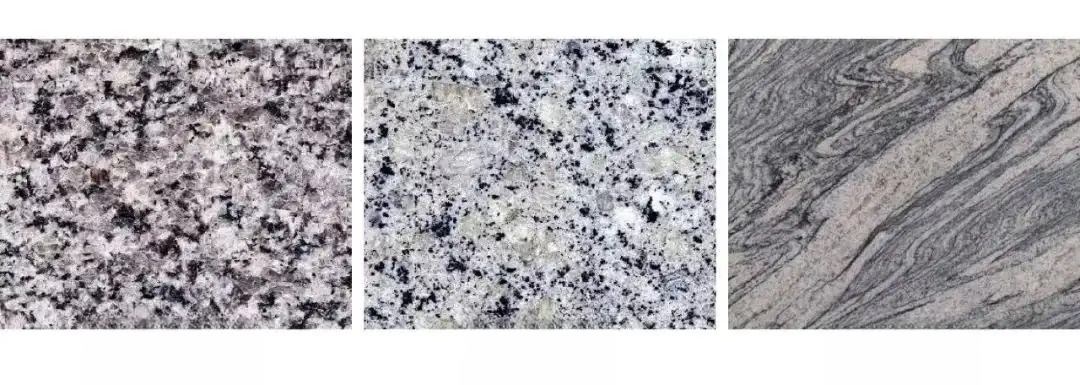

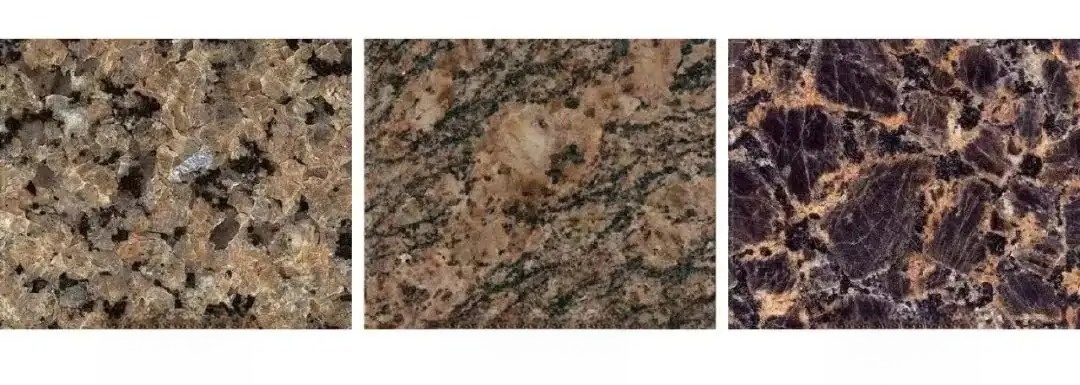

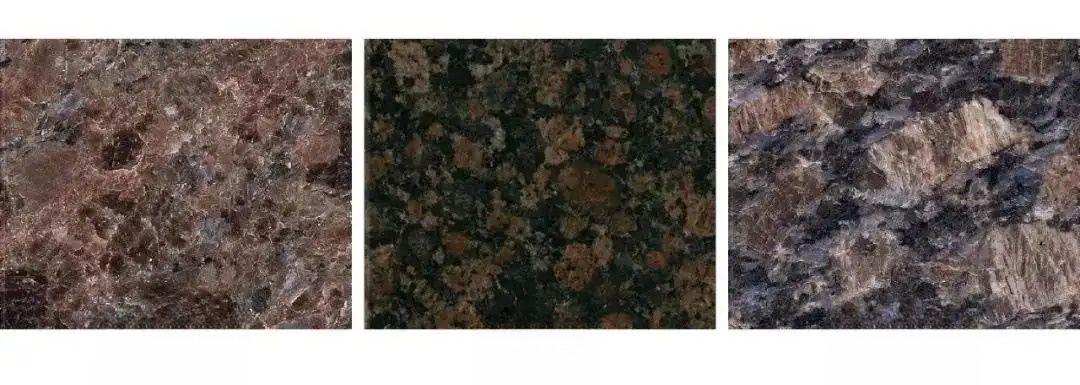

Decorative granite polished slabs are as bright as a mirror and have a gorgeous and noble decorative effect. Common types of granite polished slabs include:

Red series: Sichuan red, asbestos red, Cenxi red, tiger skin red, cherry red, Pinggu red, azalea red, rose red, Guifei red, Luqing red, Lianzhou red, etc.

Yellow-red series: Cenxi orange red, Dongliu flesh red, Lianzhou light red, Xingyang peach red, Xingyang orange red, light red small flowers, cherry red, coral flower, tiger skin yellow, etc.

White flower series: Baishihua, Baihujian, black and white flower, sesame white, white flower, Lingnan white flower, Jinan white flower, Sichuan white flower, etc.

Black series: light blue black, pure black, sesame black, Sichuan black, Yantai black, Shenyang black, Changchun black, etc.

Cyan series: sesame green, rice green, fine linen green, Jinan green, bamboo leaf green, chrysanthemum green, blue and white, reed flower green, Nanxiong green, Panxiong blue, etc.

Imported granite: Golden Diamond, South African Red, Fantasy Green, Kashmir Gold, Small Emerald Red, Dark Green Linen, American Gray Linen, Fantasy Red, Indian Red, British Brown, etc.

26

Common granite products

Natural granite products can be divided into the following categories according to different processing methods:

Axe-cut stone: The surface of the stone is hand-cut with an axe, resulting in a rough surface with regular stripes. The surface texture is rough and is used for non-slip floors, steps, bases, etc.

Machine-planed boards: The surface of the stone is mechanically planed, the surface is flat, and there are parallel planing lines. It is used for similar purposes to chopped axe boards, but the surface texture is finer.

Roughly ground slabs: The surface of the stone is roughly ground, smooth and matte, and is mainly used for walls, columns, steps, bases, etc. that require soft light effects.

Polished slabs: The surface of the stone has been finely ground and polished, and the surface is flat and bright. The granite crystal structure has clear texture and the color is gorgeous. It is used for walls, floors and columns that require a high-gloss and smooth surface effect.

27

Common applications of granite

Granite is used according to its grain size: fine grains can be polished or carved to be used as decorative panels or works of art;

Medium-sized granite is often used in the construction of bridge piers, arches, dams, harbors, plinths, foundations, and road surfaces. Coarse-grained granite is rolled into crushed stone, which is an excellent aggregate for concrete. Because granite is acid-resistant, it is also used as acid-resistant linings and containers in chemical and metallurgical production.

28

Common sense in purchasing granite

1. Check whether the stone provided is natural stone and whether its material properties meet or exceed those of natural granite (JB/T 7974-2001).

2. Quality inspection requirements: The specified value or allowable deviation of the overall dimensions is ≤±1mm in length, ±1mm in width and thickness, the specified value or allowable deviation of the surface flatness is ≤0.5mm, and the specified value or allowable deviation of the diagonal is ≤0.5mm.

3. Whether the appearance quality of the granite platform is of high quality, and whether the color, color difference and pattern of the block material are harmonious and uniform.

4. Check whether there are any external defects on the platform surface, such as missing edges, missing corners, cracks, color spots, color lines, and pits.

5. Whether the platform surface is painted with six-sided stone protective coating to ensure the waterproof and anti-fouling properties of the stone.

6. Whether the stone has passed the relevant inspections of the National Stone Quality Monitoring Center, including physical properties, radioactivity, freeze-thaw resistance, etc., and has relevant inspection reports.

29

Granite stone origin and name

Granite is a widely distributed rock found in many countries around the world. 9% of the land area (approximately 800,000 square kilometers) is made up of granite.

The following are the different types of granite and where they are found:

Asia:

Jade Qilin Origin - Vietnam

Palace Stone, Indian Flower, Coffee Pearl, Monte Carlo, Indian Black Gold Origin - India

Shanxi Black (Shanxi), Xuanwu Black (Fujian), Taishan Red (Shandong), Cenxi Red (Guangxi), Dahongmei (Hainan Island), Red (Sichuan), Black King Kong (Inner Mongolia), Bean Green (Jiangxi), Green Background and Green Flowers (Anhui), Xuelimei (Henan) Origin -

America:

Autumn Brown Origin--Canada

American White Hemp and Texas Red Origin - United States

Brazil

Europe:

Swedish mahogany stone origin - Sweden

Travertine Origin--Italy

Blue Pearl Origin--Norway

Cat Gray Stone Origin - Portugal

Rose Red Origin--Spain

Small Cui Red, Eagle Red, Carmen Red, Green Mabao, and Juhuagang are produced in Finland.

Africa:

South African Red and Forest Blue Origin - South Africa

30

Distribution of granite

Granite mineral resources are also extremely rich, with large reserves and a wide variety of varieties. According to survey data, there are more than 100 varieties of natural granite patterns and colors. Granite used for architectural decoration is named after its pattern, color characteristics and the origin of the raw materials.

Among them, the better ones include chrysanthemum green, snowflake green, and Yunlimei from Henan Jiangshi, Jinan green from Shandong Jinan, Shimian from Sichuan Shimian, bean green from Shanggao, Jiangxi, Zhongshan jade from Zhongshan, Guangdong, Guifei red, orange, pockmarked white, green and black flower, yellow and black flower from Lingqiu, Shanxi.

Granite is sourced from high-quality underground rock layers. After millions of years of natural aging, its shape is extremely stable, and there is no need to worry about deformation due to normal temperature differences. The granite platform is made of granite materials that have undergone rigorous physical testing and selection, resulting in fine crystals and a hard texture.

Because granite is a non-metallic material, it exhibits no magnetic properties and exhibits no plastic deformation. Granite platforms are highly hard, resulting in excellent precision retention. However, since granite often contains radioactive substances, its radiation level must be measured before use, prior to confirming its intended application.

Granite resources are rich and varied, and have been widely used in civil engineering since ancient times. More than 40 types of granite are used as facing stones, including Jinan Green. The main production areas are: Mount Tai and Mount Lao in Shandong, Mount Hua in Shaanxi, Xishan in Beijing, and southern Fujian.

31

Granite maintenance

Newly laid granite floors are not suitable for base wax and surface wax: Why newly laid granite floors are not suitable for base wax and surface wax? We can draw a conclusion by comparing it with marble.

The surface of marble, whether new or old, is composed of calcium carbonate crystals with large particles and therefore large pores. Even after meticulous polishing, the uneven interface can still be seen under a microscope. These tiny pores are the advantages for drop wax: when the base wax is applied, the base wax has a small molecular weight and strong permeability, coupled with capillary action, the base wax is quickly adsorbed on the marble surface to form a film. When the moisture in the base wax completely evaporates, the adsorption force is even greater. This adsorption force is crucial. It is used to counteract the force exerted on its surface due to people walking and dragging objects, so as to prevent the wax surface from leaving the ground.

As for the newly laid granite floor, its main components are crystals of quartz, mica, and feldspar, which have high density and extremely high hardness. In addition, manual polishing makes the granite surface almost non-porous. Therefore, when waxing, the base wax cannot penetrate, there is no capillary action, and of course there is no or only very weak adsorption force. Such a wax surface is easy to fall off when people walk on it, making the waxing work futile.

In view of this situation, for newly laid granite, it is only necessary to spray it with cleaning wax within six months to one year after laying to prevent stains from penetrating into the granite and maintain its surface brightness. Due to the different directions and strengths of people passing through every day, the degree of wear on the granite surface is also different. After a period of time,

32

The concept of limestone

Limestone, also known as limestone, is a carbonate rock primarily composed of calcite. It sometimes contains dolomite, clay minerals, and detrital minerals. It can be gray, off-white, gray-black, yellow, light red, or brown-red. It is generally not very hard and reacts violently with dilute hydrochloric acid.

Limestone is primarily formed in shallow marine environments. Based on its origin, limestone can be divided into granular limestone (formed by water transport and sedimentation); bioskeletal limestone; and chemical and biochemical limestone. Based on its structural structure, it can be further subdivided into bamboo-leaf limestone, spherical limestone, and massive limestone. Limestone's primary chemical component is calcium carbonate, which is easily soluble. Therefore, limestone regions often form stone forests and caves, known as karst topography.

Limestone is the main raw material for burning lime and cement, and is a flux for iron and steel making.

Biochemically generated shale often contains abundant organic debris. Limestone generally contains some dolomite and clay minerals. When the clay mineral content reaches 25% to 50%, it is called argillaceous rock. When the dolomite content reaches 25% to 50%, it is called dolomitic limestone. Limestone is widely distributed, has a uniform lithology, and is easy to mine and process, making it a widely used building material.

33

Formation of limestone

The main component of limestone is calcium carbonate, which can dissolve in water containing carbon dioxide. Generally speaking, one liter of water containing carbon dioxide can dissolve about 50 mg of calcium carbonate.

Geologists investigating the Guilin region have discovered that the water there dissolves and erodes a layer of limestone approximately as thin as a fingernail each year. While this amount of erosion may seem small, the Earth's history is incredibly long. For example, the Quaternary Period, the most recent geological period, spans approximately three million years.

Even at such a slow rate of dissolution, 900 meters can be eroded in 3 million years! Meanwhile, Guilin's isolated peaks are only a few hundred meters high, and the most common karst caves are only a few dozen meters high. However, this type of landform cannot be formed anywhere with limestone. It requires large, thick, and geologically pure limestone, along with a warm and humid climate, to develop such a perfect landform and create such beautiful natural scenery.

34

Types and distribution of limestone

Limestone is one of the most widely distributed minerals in the Earth's crust. Based on its depositional area, limestone can be divided into marine and terrestrial deposits, with the former being the most common. Based on its genesis, limestone can be divided into three types: biogenic, chemical, and secondary. Based on the different components contained in the ore, limestone can be divided into siliceous, clayey, and dolomitic limestones.

Resource Distribution: Limestone mineral resources are abundant, with over 800 deposits used for cement, solvents, and chemicals. Limestone is produced throughout China, and can be sourced locally near industrial zones in all provinces, municipalities, and autonomous regions.

Limestone deposits have been deposited in every geological era and are distributed throughout every stage of geological tectonic development. However, high-quality, large-scale limestone deposits are often found in specific strata. For example, the Middle Ordovician Majiagou Formation limestone in Northeast China and North China is an extremely important stratum for cement production. Carboniferous, Permian, and Triassic limestones are commonly used in Central South, East China, and Southwest China, while Silurian and Devonian limestones are generally used in Northwest China and Tibet. The Ordovician limestone in East China, Northwest China, and the middle and lower reaches of the Yangtze River is also an important stratum for cement production.

35

Limestone mineral composition

The mineral composition of limestone is primarily calcite, accompanied by dolomite, magnesite, and other carbonate minerals, as well as some other impurities. Magnesium appears as white limestone and magnesite, silicon oxide appears as free quartz, chalcedony and opal are distributed within the rock, and aluminum oxide combines with silicon oxide to form aluminum silicates (clay, feldspar, and mica).

Iron compounds exist in the form of carbonates (magnesite), pyrite (pyrite), free oxides (magnetite, hematite) and hydroxides (hydrous goethite); in addition, there is glauconite. Some types of limestone also contain organic matter such as coal and asphalt, sulfates such as gypsum and anhydrite, as well as compounds of phosphorus and calcium, alkali metal compounds, and compounds of strontium, barium, manganese, titanium, fluorine, etc., but the content is very low.

36

Properties of limestone

Limestone has excellent workability, polishability, and excellent cementing properties. It is insoluble in water but readily soluble in saturated sulfuric acid. It reacts with various strong acids to form corresponding calcium salts, releasing CO2. When calcined to temperatures above 900°C (generally 1000-1300°C), limestone decomposes into lime (CaO), releasing CO2. Quicklime deliquesces upon contact with water, immediately forming slaked lime [Ca(OH)2]. Slaked lime can be dissolved in water to form a slurry and readily hardens in air.

The properties of limestone can be simply understood as the chemical properties of calcium carbonate.

A carbonate rock primarily composed of calcite. Limestone is a sedimentary rock. It sometimes contains dolomite, clay minerals, and detrital minerals. It can range in color from gray, off-white, gray-black, yellow, light red, to brown-red. It is generally not very hard and reacts violently with dilute hydrochloric acid. Its structure is complex, with both a detrital and granular structure.

The clastic structure is mostly composed of particles, a micrite matrix, and spar cement. Particles, also known as granular debris, mainly include intraclasts, bioclasts, and oolitic particles. The micrite matrix is a sludge composed of calcium carbonate fines or crystals, most of which are smaller than 0.05 mm. The spar cement is a chemical precipitate that fills the pores between rock particles and consists of calcite crystals larger than 0.01 mm in diameter. The grain structure is composed of crystalline particles precipitated by chemical and biochemical processes.

37

Process characteristics and main uses of limestone

Process characteristics

Lime has excellent properties such as thermal conductivity, firmness, water absorption, air impermeability, sound insulation, polishability, good bonding properties and processability. It can be used directly as a raw ore or further processed for application.

Main Applications

Limestone is an important industrial raw material in metallurgy, building materials, chemicals, light industry, construction, agriculture and other special industrial sectors. With the development of the steel and cement industries, the importance of limestone will be further enhanced.

38

Current status, existing problems and solutions of limestone development and utilization

Limestone has a wide range of uses and is an essential raw material in various sectors of the national economy and in people's lives. It is mainly used for:

(1) Used in the construction industry to produce cement and burn lime;

(2) Used as flux in the metallurgical industry;

(3) Used in the chemical industry to produce alkali, bleaching powder and fertilizers;

(4) Used as a clarifier in the food industry;

(5) Used in agriculture to improve soil;

(6) Used as filler in the plastics industry;

(7) Widely used in the coatings industry to make various architectural coatings;

(8) Used as alkaline filler in papermaking industry;

(9) Used as basic filler for rubber in the rubber industry;

(10) Used as an adsorbent in the environmental protection industry.

Heavy calcium carbonate is a product made from natural calcite, limestone and chalk, which is mechanically crushed to a certain fineness. There are two production methods: dry and wet. The wet grinding process, which has made significant progress abroad, is still a blank in China.

In the process of producing light calcium carbonate from limestone, there is still a large gap between the particle size and crystal shape control of light calcium carbonate products and those of foreign countries. Therefore, it is necessary to further develop the deep processing industry of limestone, expand its application areas, strengthen its comprehensive utilization, increase product value and improve economic benefits.

39

Development trend of limestone

Limestone is an important industrial raw material for metallurgy, building materials, chemical industry, light industry, agriculture and other sectors. With the development of steel and cement industries, the demand for limestone will further increase.

Currently, cement production is enormous, requiring over 100 billion tons of limestone to be mined annually for cement production. It is projected that by the year 2000, national cement production will reach 300 million tons, requiring even greater quantities of limestone to be mined as raw material. Furthermore, the metallurgical and chemical industries also have a significant demand for limestone.

Therefore, the limestone industry has broad production and development prospects. In order to make limestone products have greater added value, developing deep-processing limestone products is also a future development direction.

40

Introduction to Sandstone

Sandstone is a sedimentary rock composed mainly of sand grains, with the sand content exceeding 50%. Most sandstones are composed of quartz or feldspar, which are the most common components of the Earth's crust.

Sandstone, like sand, can be any color, with brown, yellow, red, gray, and white being the most common. Sandstone cliffs are common on Earth.

41

Formation of sandstone

Sandstone is formed by debris deposition, which is different from biological deposition such as coal and chemical deposition such as gypsum and jade. The debris can be other rocks or certain mineral crystals. The material that cements these debris can be calcite, clay or silica. The particle size of the debris is between 0.1 and 2 mm. If the particle size of the debris is too small, it will form schist or shale. If it is too large, it will form conglomerate or breccia.

Sandstone containing iron oxide stripes The formation of sandstone is divided into two stages. First, the sand grains are deposited layer by layer, which may be caused by water or atmospheric transport; then, under the action of pressure, they are cemented together by calcium carbonate or silica leached from above. The iron, silicon, manganese and other elements contained in the sandstone will cause the sandstone to have different colors.

Due to differences in sedimentary environments, various sandstones have different joints, grain sizes, colors and properties, and are mainly divided into two categories: terrestrial sediments and marine sediments.

42

Sandstone structure

With the exception of biogenic structures, almost all sedimentary rock structures can be found in sandstone. Intra- and inter-laminar structures are the most obvious indicators of the type and strength of the fluids that transported the sediments. For example, cross-bedding is a hallmark of paleocurrents, and different types of grain-sequenced bedding are indicators of traction currents and turbidity currents.

43

Classification of sandstone

Sandstone is divided into coarse-grained sandstone (2-1mm), coarse-grained sandstone (1-0.5mm), medium-grained sandstone (0.5-0.25mm), fine-grained sandstone (0.25-0.125mm), and fine-grained sandstone (0.125-0.0625mm) according to the diameter of the sand particles. Among the above sandstones, the corresponding particle size content should be above 50%.

Classification by rock (mineral) type: quartz sandstone (quartz and various siliceous rock fragments account for more than 95% of the total sand-grade rock fragments) and quartz greywacke, feldspar sandstone (the debris components are mainly quartz and feldspar, of which the quartz content is less than 75% and the feldspar content exceeds 18.75%) and feldspar greywacke, lithic sandstone (the quartz content in the debris is less than 75%, the rock fragment content is generally greater than 18.755, and the rock fragment/feldspar ratio is greater than 3) and lithic greywacke.

44

Main types of sandstone

The main types of sandstone are quartz sandstone, feldspathic sandstone and lithic sandstone.

1) Quartz sandstone:

Quartz and siliceous rock fragments account for over 95% of the total sand-grade debris, with little or no feldspar, rock fragments, or heavy minerals. The debris particles are often dominated by single-crystal quartz, with good roundness and sorting, and the highest compositional and structural maturity.

It has a low matrix content and is supported by particles. When the matrix content is > 15%, it is called quartz greywacke. Quartz greywacke primarily forms in stable tectonic environments with quasi-plain terrain. The parent rock undergoes long-term weathering and denudation, and the resulting products are mostly slowly deposited in marine environments (such as beaches) under the intense selection and repeated abrasion of waves and currents. It often coexists with carbonate deposits, forming the quartz sandstone-marine carbonate formation, such as the Upper Precambrian in the northern half of the North China Platform.

2) Feldspathic sandstone:

Feldspar fragments account for over 25% of the total sand-grade fragments. Quartz content is <75%, and may contain significant amounts of mica and heavy minerals. The cement is primarily calcareous and ferrous, often containing a clay matrix. When the matrix exceeds 15%, it is classified as feldspar greywacke.

The clastic particles are generally well-sorted and of medium roundness. Arkose sandstone often appears pale yellow, fleshy pink, or greenish-gray. Based on the conditions of its formation, arkose sandstone can be divided into three categories: tectonic arkose sandstone, basement arkose sandstone, and climatic arkose sandstone. Arkose sandstone is generally formed in areas of intense tectonic movement, where the parent rock is granite or granite gneiss, in dry, cold climates, and where physical weathering is predominant, resulting in intense erosion and rapid accumulation.

Most are continental deposits, with marine deposits being rare. They often accumulate in piedmont or intermontane basins. Many feldspathic sandstones have been found to form within continental rifts. The Sinian System in Tangshan, Hebei, contains feldspathic sandstones containing over 50% feldspar.

3) Lithic sandstone:

Rock fragments account for over 25% of the total sand-grade debris. Quartz content is <75%, and may contain a small amount of feldspar (<10%). Heavy minerals are high and complex in nature. Cement is often siliceous and carbonate, often containing impurities.

When the matrix content is > 15%, it is classified as lithic greywacke. The roundness and sorting of the clastic particles range from medium to poor. They are often light gray, gray-green, or dark gray. The composition of the lithic debris is closely related to the properties of the parent rock in the source area and can be further divided into rock types based on its composition.

Lithic sandstone is a type of sandstone with low compositional and structural maturity, mainly formed in piedmont or intermontane depressions in areas with strong tectonic changes.

45

Composition of sandstone

Chemical composition

The chemical composition of sandstone varies greatly, depending on the composition of the debris and fill. The chemical composition of sandstone is mainly SiO2 and Al2O3, and the SiO2/Al2O3 ratio is the hallmark of mature and immature sandstone.

Crumb composition

Quartz is the primary mineral fragment in sandstone. It is the most stable under surface conditions and is the main component of most sandstones. It is often used as an indicator of parent rock. The content of feldspar in sandstone is second only to quartz, and in some cases exceeds quartz.

It is generally believed that the content of feldspar debris is affected by climate, the intensity of crustal movement, and the properties of the parent rock. Rock fragments are a direct indicator of the parent rock. In sandstone, they are mostly volcanic debris or fine-grained, relatively stable sedimentary and metamorphic debris.

Heavy minerals are a set of minerals in sandstone with a specific gravity greater than 2.87. Their content is generally less than 1%. The typological characteristics and assemblage of heavy minerals (combined with the assemblage of light minerals) are valuable for reconstructing parent rock types, conducting stratigraphic correlations, and tracing terrigenous sources.

gap filler

It includes chemical cements and clastic matrix. Silicity and carbonates dominate the cements. Siliceous cements are generally secondary, overgrown quartz, with chalcedony and opal being less common. Calcite is the most common carbonate cement, while dolomite and siderite are less common.

Siliceous cements are more common in older sandstones, while carbonate cements are more common in younger sandstones from the Mesozoic and later periods. This is generally believed to be due to the different stabilities of the two types of cements, or to the ease with which carbonate cements are leached away.